January 2019

| Business World Magazine

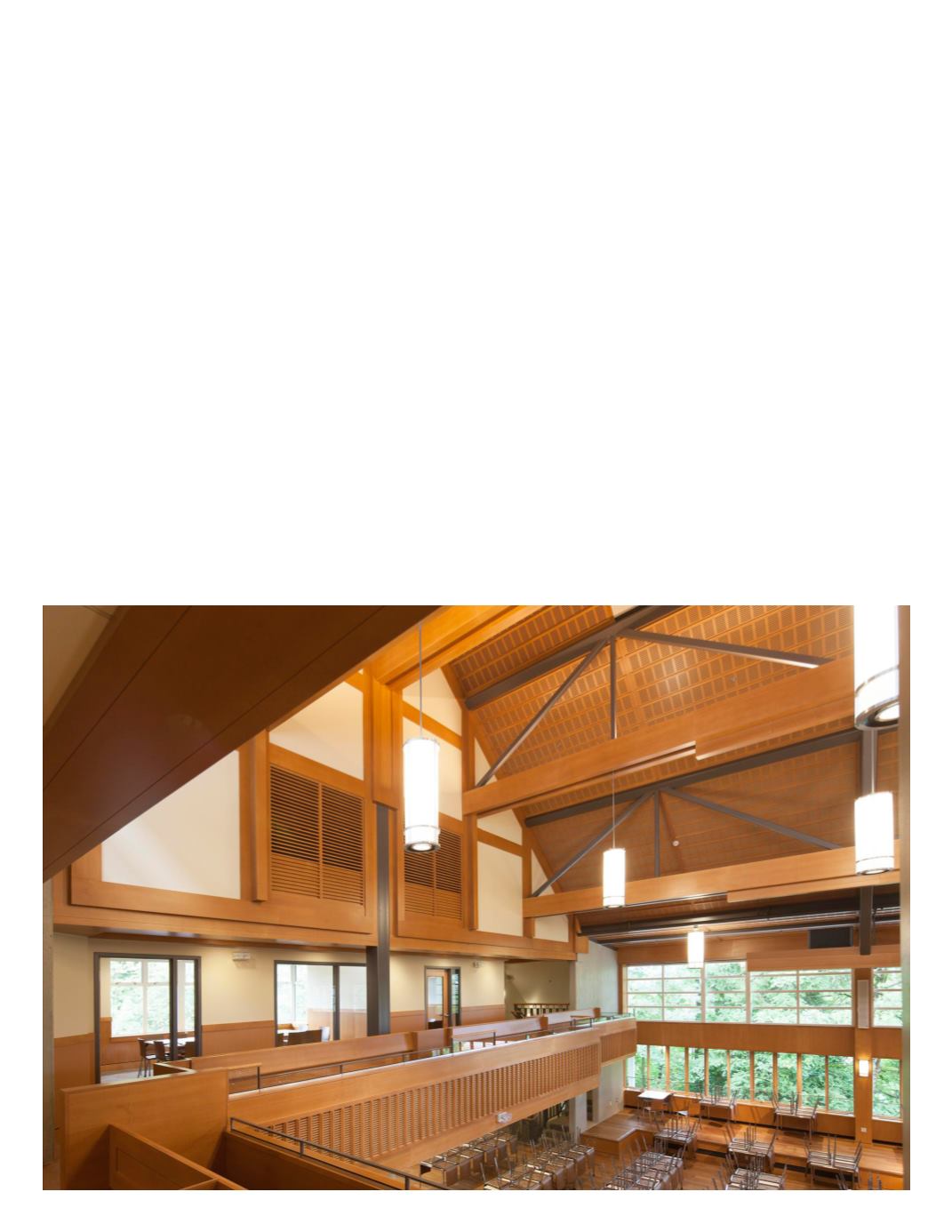

doing just custom wood products into plastics,

glazing, upholstery, metal fabrications, solid

surfacing material and stone. Those are all

integral components of many of their current

millwork projects – which include large insti-

tutional projects such as schools, hospitals,

banks, office buildings, and much more.

“We’re a custom operation, so there are

very little types of work that we can’t do,” Dave

says.

The majority of Midwest Millwork’s cli-

ents are main building contractors, and their

projects can range in value up to $3 million.

Because the majority of their jobs are pub-

licly funded, they generate most of their work

through the tender process. But while price is

very important, it’s usually not the defining rea-

son Midwest Millwork is selected.

“We separate ourselves from our competi-

tors by the quality of our work,” Dave says.

“We’re not always the most competitive in

terms of dollars and cents, because we sim-

ply won’t back off on our quality. We won’t cut

corners and reduce what we do. We keep our

standards very high.”

Dave admits that those standards mean

that they’re not right for every job: “Sometimes

people want things done as cheaply as they