February 2014

| Business World Magazine | 107

so high as to shiver the timbers of any sailor.

Robert had designed the fueling ship, formu-

lated the plan and gained some traction, but

alas, this concept too drowned in the water.

And it wasn’t as if the Kings weren’t al-

ready successful. They had what Kelly de-

scribes as “a working business” in a generator

dealership that was doing very well. Robert

was already kept sufficiently busy having

been contracted to service andmaintain gen-

erators throughout the community. So, with

respect to the new idea, no one could blame

Kelly for asking her husband, “Why now?”

Robert made his convincing case, a case that

encompassed not only cost and supply issues

relative to the use of petroleum products, but

also environmental concerns arising from the

discarded deluge of used cooking oils that

were mucking-up area landfills. Robert’s pro-

posal was to devise a method for capturing

and refining that material to create biodiesel.

“Bio-what?” was Kelly’s initial response.

INDUSTRY PIONEER

It took only a year following that conversa-

tion, and in 1996 the Kings processed their

first biodiesel and establishedPacific Biodies-

el. Now headquartered in Kahului, Hawaii,

the firm’s first small-scale plant was the first

commercially viable biodiesel operation in

If you just check your hot-oil on a regular basis you

could practically eliminate unplanned shutdown or loss of

production. The easy way to do this is by conducting a

Fluid Analysis. Because Fluid Analysis isn’t just to check

your fluid, it’s to test your system.

When we test your fluid (we suggest annually or more

frequently for demanding service) the values we get from

boiling range, viscosity, and acidity tell us what’s going

on in there. Better yet, together with a one-to-one system

review with you, those same test results can help pinpoint

emerging issues with oxidation, over-heating, or possible

mismatches in those interrelated components that could

lead to a downtime-causing problem.

This can help you keep the system up when it’s

supposed to be up, and know in advance if any

corrections are needed for when you do have scheduled

downtime. Your system runs better, your fluid last longer,

and your process earns its keep.

®

®

31 Portland Road

West Conshohocken PA 19428 USA

800-222-3611

610-941-4900 • Fax: 610-941-9191

Did you know that 90% of heat transfer

fluid breakdowns are caused by

equipment issues?

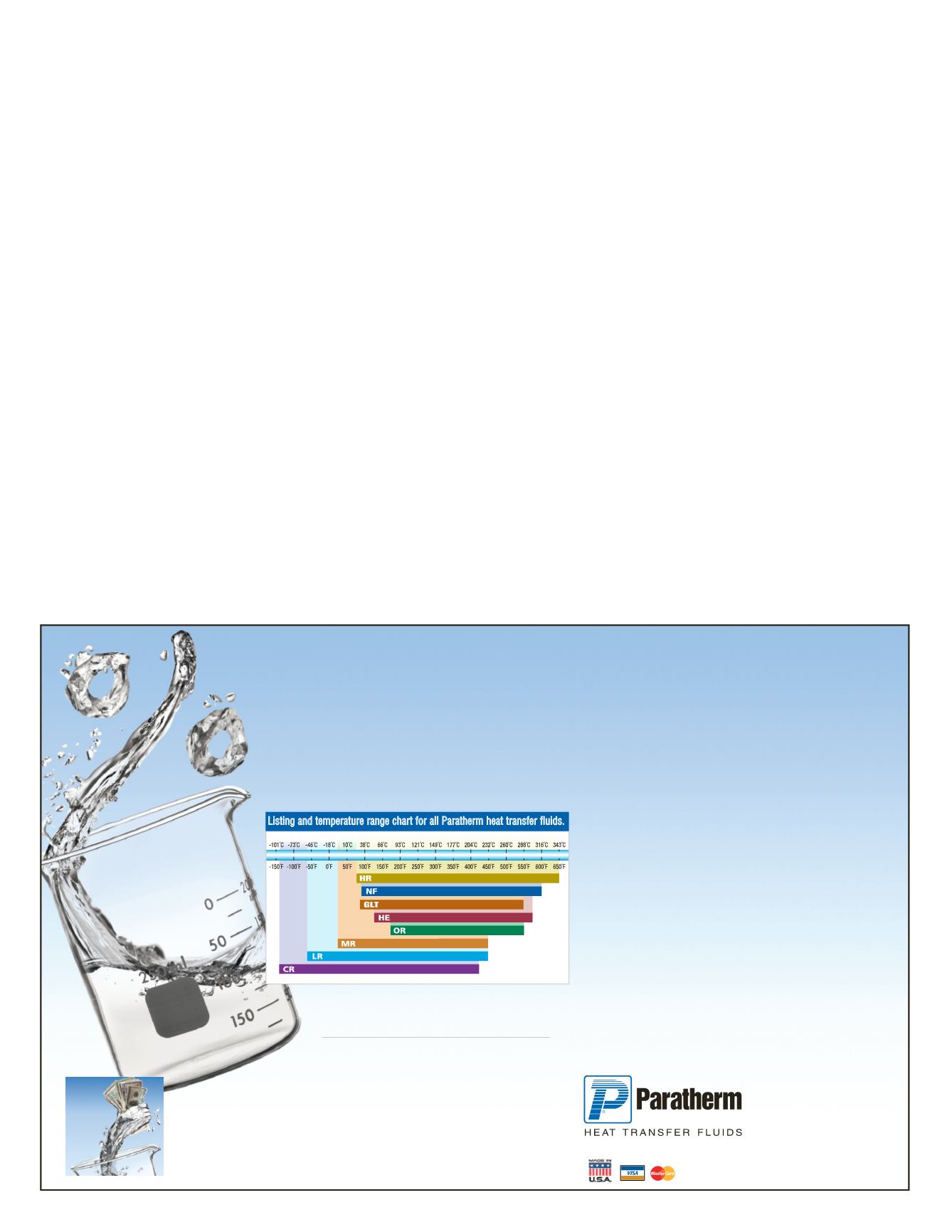

Listing and temperature range chart for all Paratherm heat transfer fluids.

Make your system

more profitable,

more sustainable.

See the sampling process

in a 1-minute video at

Paratherm CR

®

HTF

Paratherm MR

®

HTF

Paratherm LR

™

HTF

Paratherm HR

™

HTF

Paratherm HE

®

HTF

Products

Paratherm NF

®

HTF

Paratherm OR

®

HTF

Paratherm GLT

™

HTF

Paratherm SC

®

Cleaner

Paratherm LC

™

Cleaner

Paratherm AC

™

Cleaner

Fluid Analysis

Fluid Maintenance

Training

Troubleshooting

Consulting

Services