6 | City of Swift Current

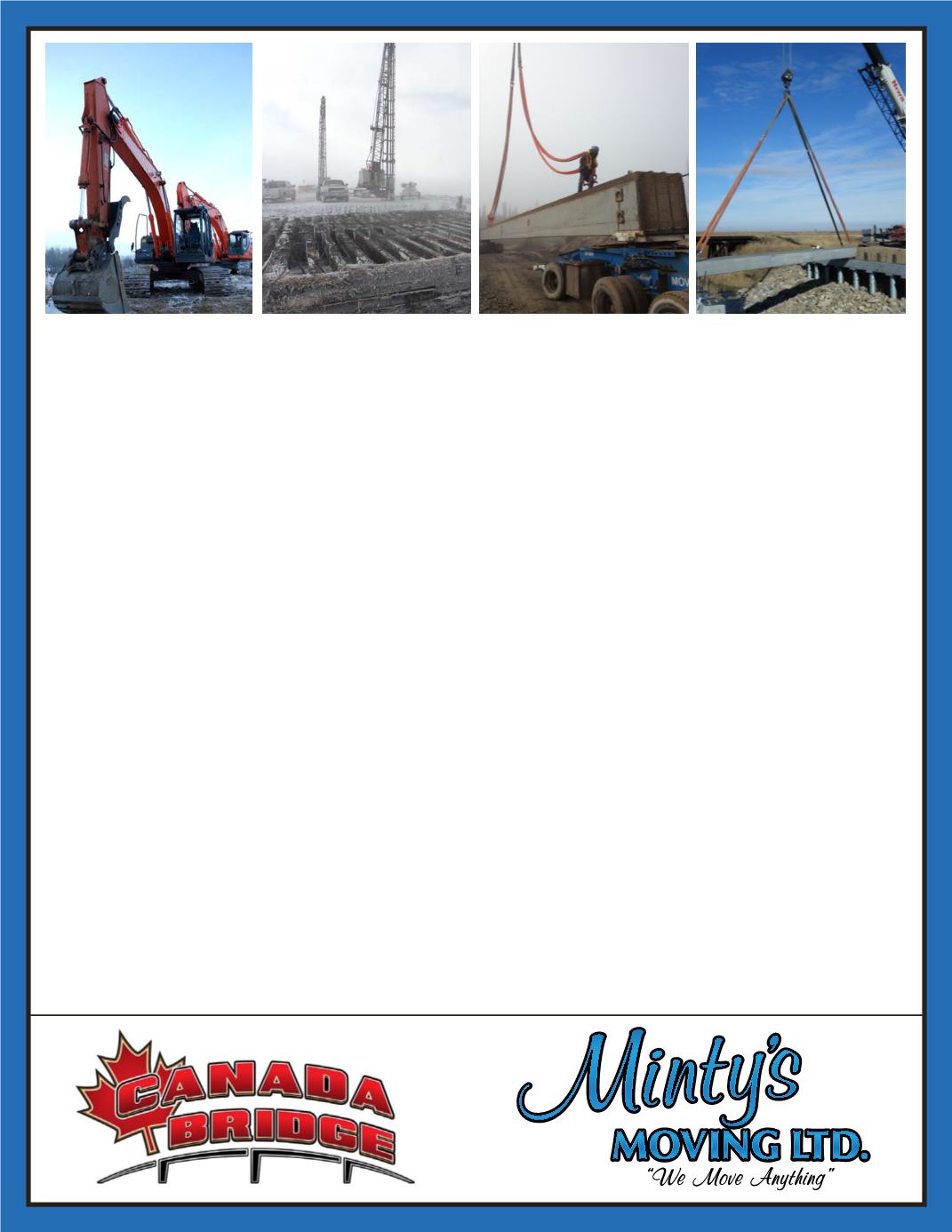

Installing multiple pieces of a nearly 20-ton bridge might sound

like a remarkably onerous undertaking but it’s all in a few days’

work – literally – for Manitoba-based Minty’s Moving Ltd. (MML).

A family business that began when founder Vic Minty moved a

chicken coop for his uncle back in 1945, Minty’s has experienced

consistent growth and has gradually branched out to more com-

plex moves including houses, sheds, barns and grain elevators.

The company began hauling and erecting bridge girders for local

general contractors about 20 years ago before ultimately develop-

ing the expertise that allowed it to take over general contracting

duties for complete bridge jobs.

These days, MML builds about 20 highway bridges and 20 tempo-

rary detour bridges per year while also undertaking about 20 more

repair jobs on highway bridges annually. It still takes on all sorts

of large moving tasks – houses, sheds, grain elevators, bridges

and hydro transformers and reactors – and has recently begun

dabbling in the design, build, finance and maintenance of bridges.

MML was awarded a $141,280 contract for the construction of the

foundation and the erection of a steel truss pedestrian bridge on

the 13th hole at the City of Swift Current’s Chinook Golf Course,

an addition that allows golfers to cross over an on-course creek

rather than having to travel along the 12th fairway while walking

around it.

The installation was the final portion of a $331,000 capital proj-

ect that also included the bridge’s supply, fabrication and delivery.

The two halves of the bridge – manufactured by Eagle Bridge Co.

– were brought to the work site, at which time the Minty’s crew

arrived to prepare the area for installation.

Upon arrival, Minty’s performed a survey and marked pile loca-

tions before four screw piles were installed and cut-off elevations

were determined and transferred to the piles. Pile cap plates and

gussets were welded into place and after excavation, two back

timber walls were installed. Backfilling and compaction of abut-

ment material began while clay was placed around the outside of

the abutment and compacted.

Upon reaching the desired shape, steel pile caps were fabricated

on site and placed on top of the previously installed cap plates.

Thirty wooden swamp mats, measuring eight feet by 14 feet, were

placed to provide a firm base for the crane, at which time the two

halves of the bridge were bolted together and hoisted into posi-

tion. The pile caps were then positioned and welded down, the

retaining plates and hardware were installed and the crane was

cut loose from the bridge.

Construction of the ramps was completed on either side of the

bridge and landscaping was also finalized while the remainder of

necessary welding was done and the Minty’s crew left the site

upon final inspection and approval from golf course superinten-

dent Doug Leavins and consulting firm engineers Trevor Fetich and

Brian Bollingbroke.

“No project gets done successfully without teamwork and we

were able to have success thanks to the others involved on the

project,” says Bill Hopkins, site supervisor for Minty’s. “They were

absolute gems to work with and we thank them very much for the

cooperation they provided.”

6 | City of Swift Current

Installing multiple pieces of a nearly 20-ton bridge might sound

like a remarkably onerous undertaking but it’s all in a few days’

work – literally – for Manitoba-based Minty’s Moving Ltd. (MML).

A family business that began when founder Vic Minty moved a

chicken coop for his uncle back in 1945, Minty’s has experienced

consistent growth and has gradually branched out to more com-

plex moves including houses, sheds, barns and grain elevators.

The company began hauling and erecting bridge girders for local

general contractors about 20 years ago before ultimately develop-

ing the expertise that allowed it to take over general contracting

duties for complete bridge jobs.

These days, MML builds about 20 highway bridges and 20 tempo-

rary detour bridges per year while also undertaking about 20 more

repair jobs on highway bridges annually. It still takes on all sorts

of large moving tasks – houses, sheds, grain elevators, bridges

and hydro transformers and reactors – and has recently begun

dabbling in the design, build, finance and maintenance of bridges.

MML was awarded a $141,280 contract for the construction of the

foundation and the erection of a steel truss pedestrian bridge on

the 13th hole at the City of Swift Current’s Chinook Golf Course,

an addition that allows golfers to cross over an on-course creek

rather than having to travel along the 12th fairway while walking

around it.

The installation was the final portion of a $331,000 capital proj-

ect that also included the bridge’s supply, fabrication and delivery.

The two halves of the bridge – manufactured by Eagle Bridge Co.

– were brought to the work site, at which time the Minty’s crew

arrived to prepare the area for installation.

Upon arrival, Minty’s performed a survey and marked pile loca-

tions before four screw piles were installed and cut-off elevations

were determined and transferred to the piles. Pile cap plates and

gussets were welded into place and after excavation, two back

timber walls were installed. Backfilling and compaction of abut-

ment material began while clay was placed around the outside of

the abutment and compacted.

Upon reaching the desired shape, steel pile caps were fabricated

on site and placed on top of the previously installed cap plates.

Thirty wooden swamp mats, measuring eight feet by 14 feet, were

placed to provide a firm base for the crane, at which time the two

halves of the bridge were bolted together and hoisted into posi-

tion. The pile caps were then positioned and welded down, the

retaining plates and hardware were installed and the crane was

cut loose from the bridge.

Construction of the ramps was completed on either side of the

bridge and landscaping was also finalized while the remainder of

necessary welding was done and the Minty’s crew left the site

upon final inspection and approval from golf course superinten-

dent Doug Leavins and consulting firm engineers Trevor Fetich and

Brian Bollingbroke.

“No project gets done successfully without teamwork and we

were able to have success thanks to the others involved on the

project,” says Bill Hopkins, site supervisor for Minty’s. “They were

absolute gems to work with and we thank them very much for the

cooperation they provided.”

6 | City of Swift Current

Installing multiple pieces of a nearly 20-ton bridge might sound

like a remarkably onerous undertaking but it’s all in a few days’

work – literally – for Manitoba-based Minty’s Moving Ltd. (MML).

A family business that began when founder Vic Minty moved a

chicken coop for his uncle back in 1945, Minty’s has experienced

consistent growth and has gradually branched out to more com-

plex moves including houses, sheds, barns and grain elevators.

The company began hauling and erecting bridge girders for local

general contractors about 20 years ago before ultimately develop-

ing the expertise that allowed it to take over general contracting

duties for complete bridge jobs.

These days, MML builds about 20 highway bridges and 20 tempo-

rary detour bridges per year while also undertaking about 20 more

repair jobs on highway bridges annually. It still takes on all sorts

of large moving tasks – houses, sheds, grain elevators, bridges

and hydro transformers and reactors – and has recently begun

dabbling in the design, build, finance and maintenance of bridges.

MML was awarded a $141,280 contract for the construction of the

foundation and the erection of a steel truss pedestrian bridge on

the 13th hole at the City of Swift Current’s Chinook Golf Course,

an addition that allows golfers to cross over an on-course creek

rather than having to travel along the 12th fairway while walking

around it.

The installation was the final portion of a $331,000 capital proj-

ect that also included the bridge’s supply, fabrication and delivery.

The two halves of the bridge – manufactured by Eagle Bridge Co.

– were brought to the work site, at which time the Minty’s crew

arrived to prepare the area for installation.

Upon arrival, Minty’s performed a survey and marked pile loca-

tions before four screw piles were installed and cut-off elevations

were determined and transferred to the piles. Pile cap plates and

gussets were welded into place and after excavation, two back

timber walls were installed. Backfilling and compaction of abut-

ment material began while clay was placed around the outside of

the abutment and compacted.

Upon reaching the desired shape, steel pile caps were fabricated

on site and placed on top of the previously installed cap plates.

Thirty wooden swamp mats, measuring eight feet by 14 feet, were

placed to provide a firm base for the crane, at which time the two

halves of the bridge were bolted together and hoisted into posi-

tion. The pile caps were then positioned and welded down, the

retaining plates and hardware were installed and the crane was

cut loose from the bridge.

Construction of the ramps was completed on either side of the

bridge and landscaping was also finalized while the remainder of

necessary welding was done and the Minty’s crew left the site

upon final inspection and approval from golf course superinten-

dent Doug Leavins and consulting firm engineers Trevor Fetich and

Brian Bollingbroke.

“No project gets done successfully without teamwork and we

were able to have success thanks to the others involved on the

project,” says Bill Hopkins, site supervisor for Minty’s. “They were

absolute gems to work with and we thank them very much for the

cooperation they provided.”

6 | City of Swift Current

Installing multiple pieces of a nearly 20-ton bridge might sound

like a remarkably onerous undertaking but it’s all in a few days’

work – literally – for Manitoba-based Minty’s Moving Ltd. (MML).

A family business that began when founder Vic Minty moved a

chicken coop for his uncle back in 1945, Minty’s has experienced

consistent growth and has gradually branched out to more com-

plex moves including houses, sheds, barns and grain elevators.

The company began hauling and erecting bridge girders for local

general contractors about 20 years ago before ultimately develop-

ing the expertise that allowed it to take over general contracting

duties for complete bridge jobs.

These days, MML builds about 20 highway bridges and 20 tempo-

rary detour bridges per year while also undertaking about 20 more

repair jobs on highway bridges annually. It still takes on all sorts

of large moving tasks – houses, sheds, grain elevators, bridges

and hydro transformers and reactors – and has recently begun

dabbling in the design, build, finance and maintenance of bridges.

MML was awarded a $141,280 contract for the construction of the

foundation and the erection of a steel truss pedestrian bridge on

the 13th hole at the City of Swift Current’s Chinook Golf Course,

an addition that allows golfers to cross over an on-course creek

rather than having to travel along the 12th fairway while walking

around it.

The installation was the final portion of a $331,000 capital proj-

ect that also included the bridge’s supply, fabrication and delivery.

The two halves of the bridge – manufactured by Eagle Bridge Co.

– were brought to the work site, at which time the Minty’s crew

arrived to prepare the area for installation.

Upon arrival, Minty’s performed a survey and marked pile loca-

tions before four screw piles were installed and cut-off elevations

were determined and transferred to the piles. Pile cap plates and

gussets were welded into place and after excavation, two back

timber walls were installed. Backfilling and compaction of abut-

ment material began while clay was placed around the outside of

the abutment and compacted.

Upon reaching the desired shape, steel pile caps were fabricated

on site and placed on top of the previously installed cap plates.

Thirty wooden swamp mats, measuring eight feet by 14 feet, were

placed to provide a firm base for the crane, at which time the two

halves of the bridge were bolted together and hoisted into posi-

tion. The pile caps were then positioned and welded down, the

retaining plates and hardware were installed and the crane was

cut loose from the bridge.

Construction of the ramps was completed on either side of the

bridge and landscaping was also finalized while the remainder of

necessary welding was done and the Minty’s crew left the site

upon final inspection and approval from golf course superinten-

dent Doug Leavins and consulting firm engineers Trevor Fetich and

Brian Bollingbroke.

“No project gets done successfully without teamwork and we

were able to have success thanks to the others involved on the

project,” says Bill Hopkins, site supervisor for Minty’s. “They were

absolute gems to work with and we thank them very much for the

cooperation they provided.”