har vest, and we tr y to work with

landowners and try to teach landowners

what’s good for their property. There are a

few out there that do pay attention to that,

and we’ve had comments already that they

like our philosophy and they like the

position we take on the environmental

impact, so they will continue to work with

us.”

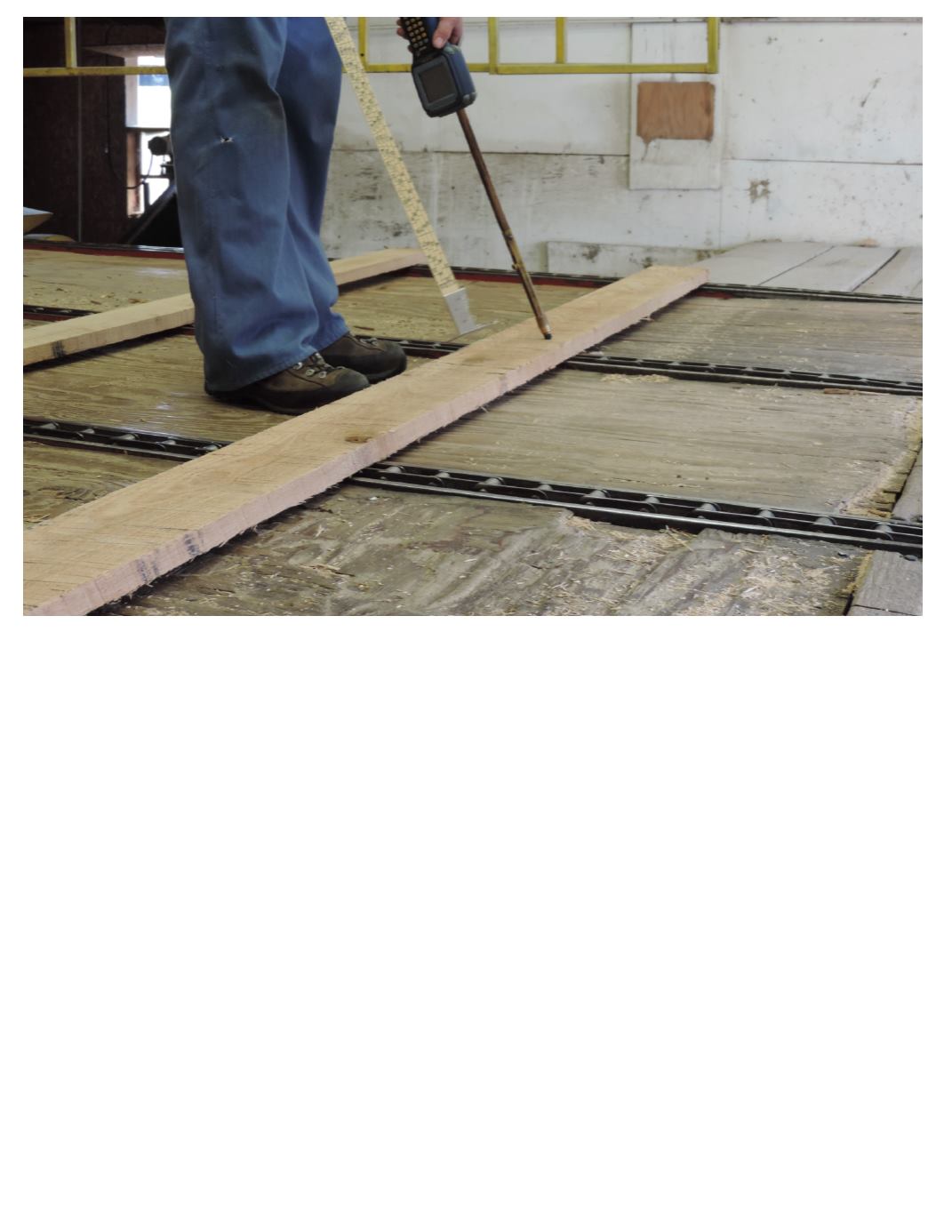

Yoder Lumber works closely with certified

foresters to ensure proper harvesting, and

master loggers use advanced equipment and

techniques to minimize residual damage to

the forest.

Their facilities are designed to use as much

of every log as possible to reduce waste.

One-hundred percent of the wood-fiber

by-products are used or sold, eliminating

the need to send any by-products to

landfills. A significant portion of the wood

by-products are used toheat 10 kilns, as well

as their offices andmanufacturing facilities.

As much he covets the positive feedback

from the

outside, however, Yoder saidmany

of his best moments on the job have come

174 | BusinessWorld |

May 2014