55 guys, as much as can use it with a crew of

125 guys on the shop floor,” Wixom said.

“It’s our ability to ramp up or ramp down –

depending on the customer’s needs and the

type of machinery required to process the

product that they require – and then our

organization inour up-front process.

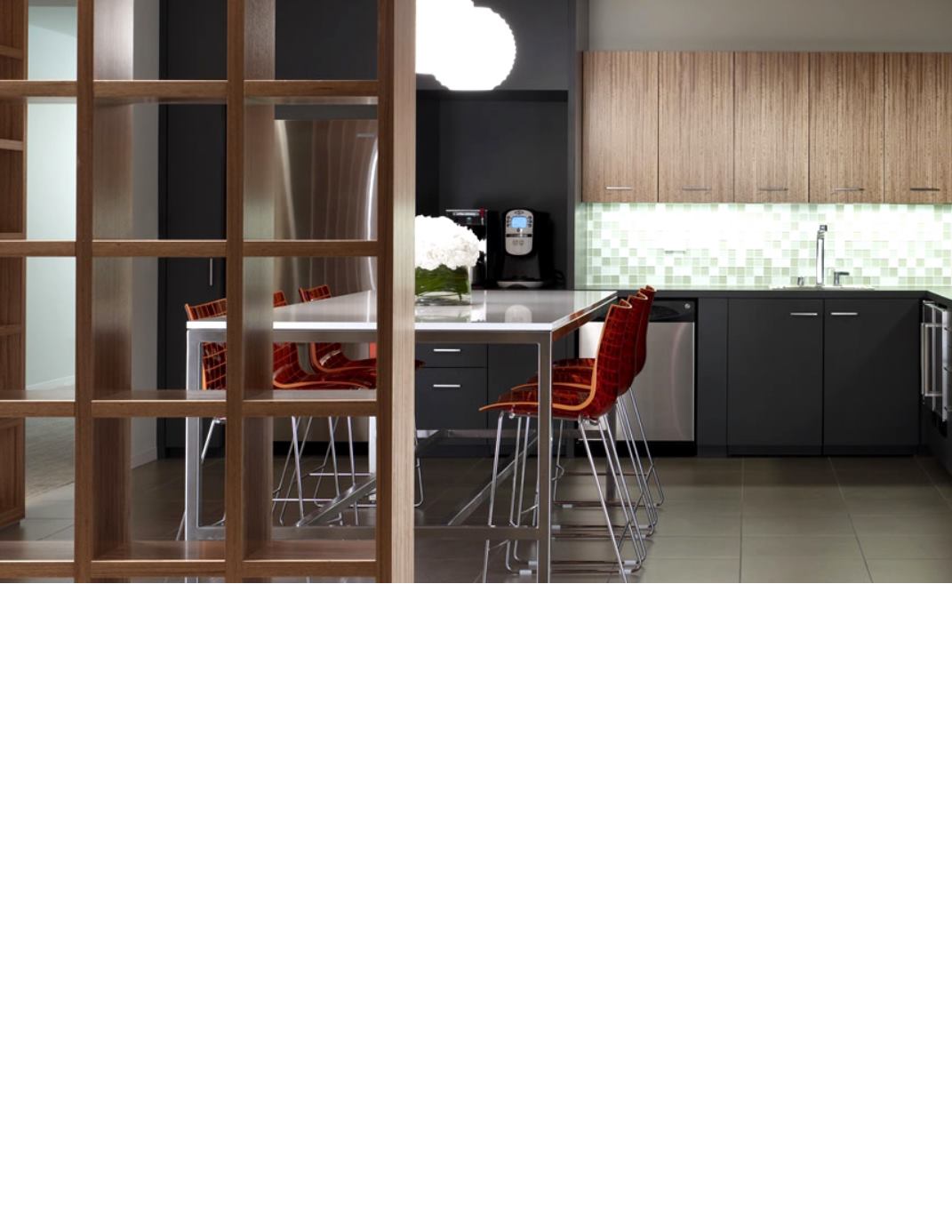

“Our shop drawings, we believe, reflect as

much if not more detail than anyone else in

our competitive industry. Though we

strongly feel we have the best carpenters in

the world on our shop floor, we still like to

give them what we affectionately refer to as

Lego drawings. We take the guesswork out

of those drawings so that their crafts-

manship can show in the finite details.”

Still, no matter how much the front end

may change, the back end remains a hands-

onproposition.

In fact, Fetzer has eschewed a trend toward

automating the finish process with a

rolling-line systemthat’s become popular in

the industry, in favor of a throwback to its

TheodoreRoosevelt-era roots.

“It’s the control you get,” Wixom said,

156 | BusinessWorld |

July-August 2014