10 | Business World Magazine |

July 2013

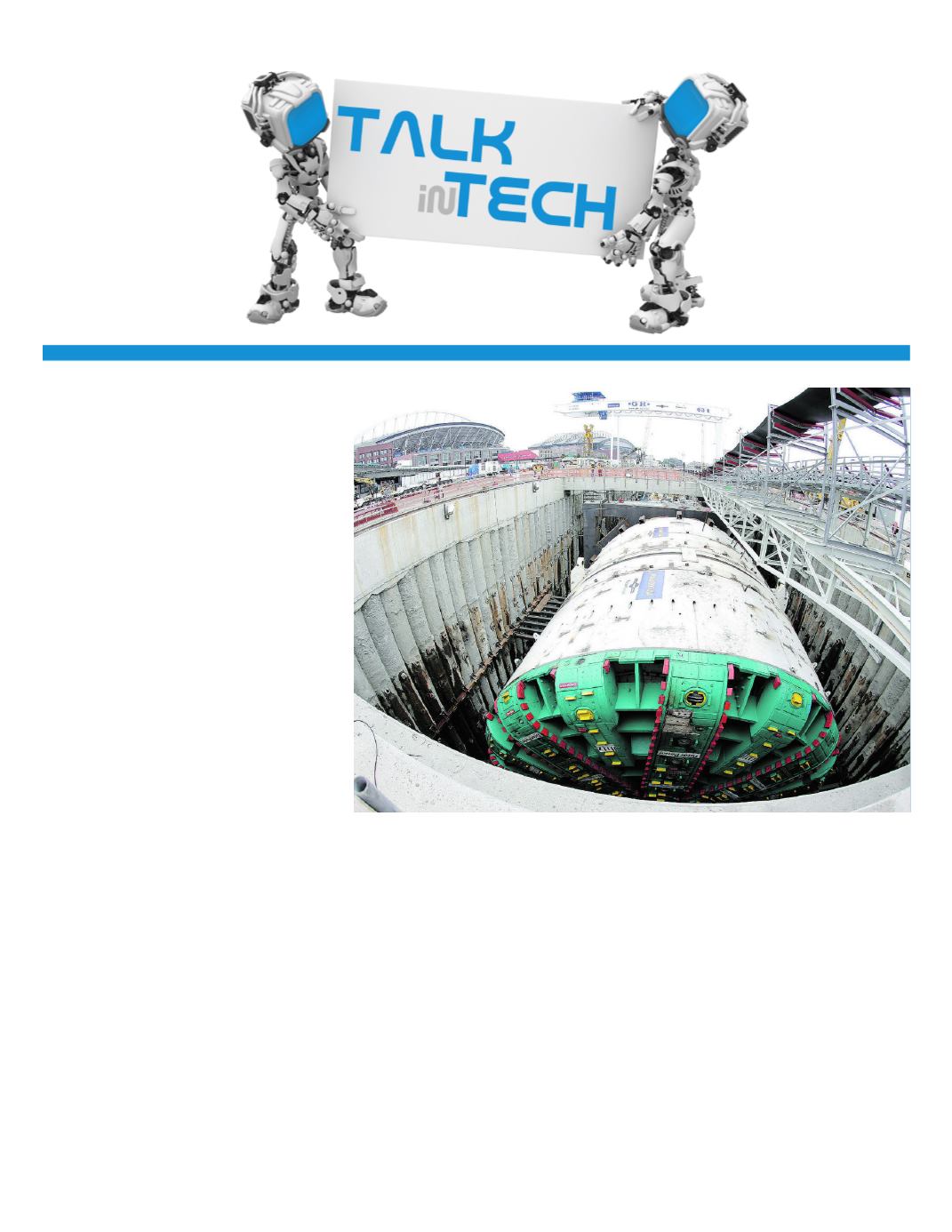

Weighing more than 83 tons and

reaching a height of five stories,

Bertha is indeed big, but she’s also

beautiful, especially to Washington

State Department of Transportation

workers wanting to expedite con-

struction of the new Route 99 tun-

nel. The tunnel, which will extend

beneath downtown Seattle, is part of

a $3 billion project that replaces the

aging infrastructure associated with

theAlaskanWayViaduct. Aftermore

than a year of development, the world’s largest tun-

neling machine (dubbed as “Bertha”) was recently

lowered into an 80 foot pit to begin boring through

some two miles of terra firma. Valued at more than

$80 million, Bertha was manufactured by Hitachi

Zosen in Osaka, Japan. Its drill head is more than

57 feet in diameter and equipped with more than

600 steel bits and spinning disks to effectively bore

through dirt and rock. Traditionally, these innova-

tions in excavation have to be frequently inspected

at varying stages of depth, which is problematic for

humans because in an enclosed tunnel, the pressure

at depths of only 200 feet is essentially the same as

that which exists under 165 feet of water. Replac-

ing cutting tools has generally required workers to

spend time in a hyperbaric chamber, yet with Ber-

tha, workers can make needed modifications from

inside the machine itself. Bertha is large enough to

accommodate work frombehind the drill face at at-

mospheric pressure similar to aboveground condi-

tions. An automated system basically helps retract

the cutting components into a chamber, allowing

workers to make repairs aided by hydraulic pulleys

and other mechanisms that expedite the process.

Barring any birthing pains, Bertha is anticipated to

crawl along some 30 feet per day, and the tunnel is

expected to be ready for motorists by 2015.

Birthing

Bertha