Business World |

March 2015

50

which are both free of hazardous chemicals.

Their equipment is also “all rigged up” with

an Emergency Shut Down (ESD) system

that automatically shuts the engine down if

a leak occurs at any point during the opera-

tion − which is unlikely to happen due to the

thick insulation in their tubing − thus negat-

ing any potential contamination.

ONE STOP SHOP

In addition to beingmore cost-effective, safer

and environmentally-friendly than conven-

tional well abandonment methods, the Nu-

Wave system is also much simpler and tidier.

Tim explains the seamless process in detail.

“When we get to the site, we pull up to the

well, break the top of the well off, unload our

equipment and lower our tool down into the

well,” he says. “Once it’s in place, we kick the

high-pressure water on. When it gets up to

pressure, we turn the sand on. Once it kicks

in and we pierce through all the casings, we

turn the hydraulics on, which starts rotating

the tool down below. Once it reaches full ro-

tation, we shut the sand off and wait a few

minutes before shutting the water off.”

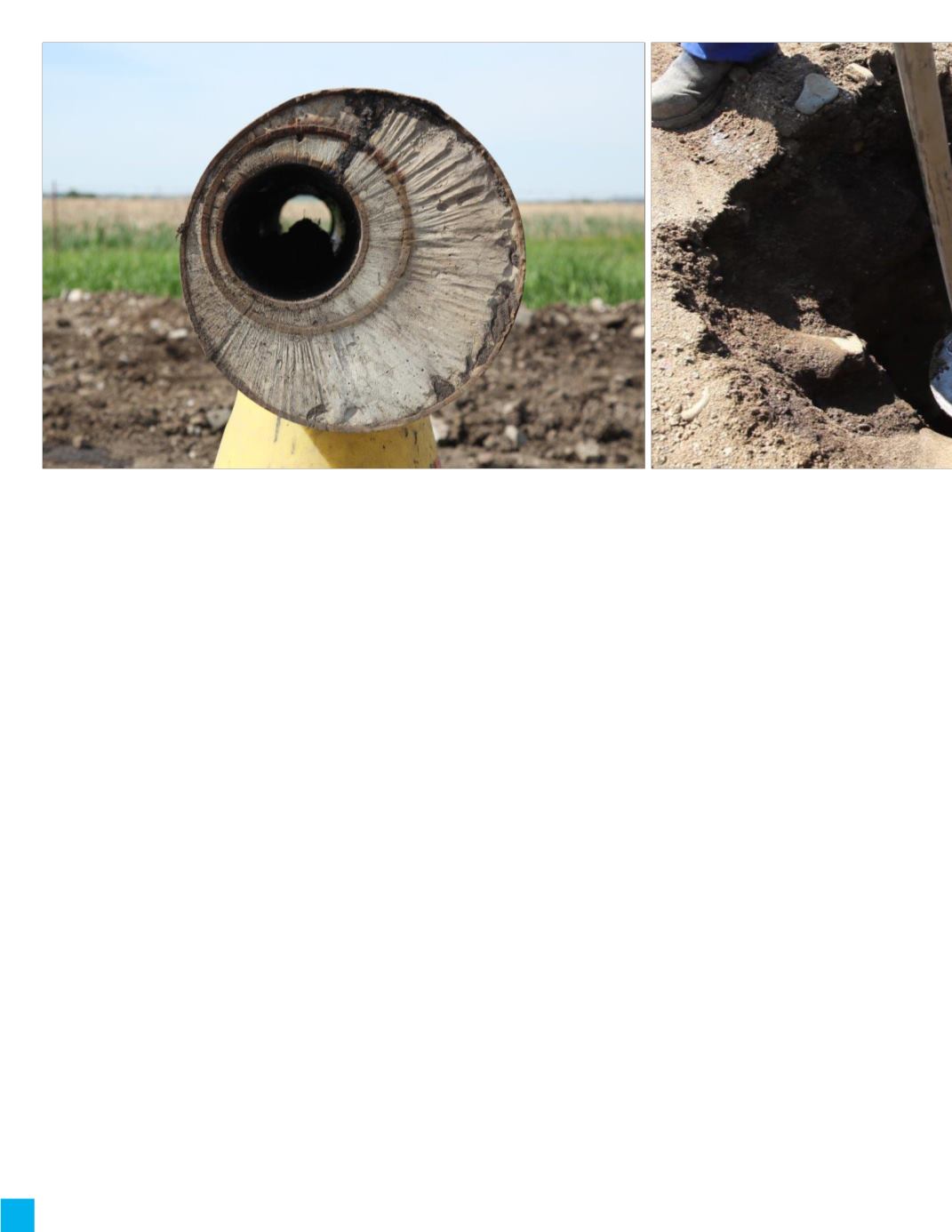

“We then pull our tool out and use a hoe to

hook onto the wellhead to pull it out,” he

adds. “At that point, we insert the capping

mechanism − called a centralizer − which

is approved by the board. It’s then lowered

down into the wellbore with the location

welded on it. Once it’s in place, we basically

fill the hole in with the hoe and load up all