Out with the old, in with the Nu

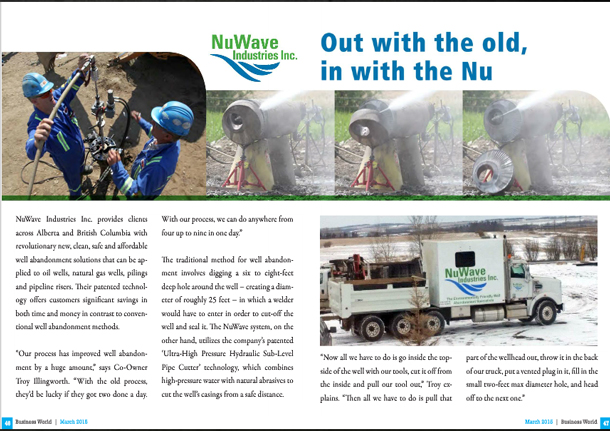

NuWave Industries Inc. provides clients across Alberta and British Columbia with revolutionary new, clean, safe and affordable well abandonment solutions that can be applied to oil wells, natural gas wells, pilings and pipeline risers. Their patented technology offers customers significant savings in both time and money in contrast to conventional well abandonment methods.

“Our process has improved well abandonment by a huge amount,” says Co-Owner Troy Illingworth. “With the old process, they’d be lucky if they got two done a day. With our process, we can do anywhere from four up to nine in one day.”

The traditional method for well abandonment involves digging a six to eight-feet deep hole around the well − creating a diameter of roughly 25 feet − in which a welder would have to enter in order to cut-off the well and seal it. The NuWave system, on the other hand, utilizes the company’s patented ‘Ultra-High Pressure Hydraulic Sub-Level Pipe Cutter’ technology, which combines high-pressure water with natural abrasives to cut the well’s casings from a safe distance.

“Now all we have to do is go inside the topside of the well with our tools, cut it off from the inside and pull our tool out,” Troy explains. “Then all we have to do is pull that part of the wellhead out, throw it in the back of our truck, put a vented plug in it, fill in the small two-feet max diameter hole, and head off to the next one.”

According to Co-Owner Tim Sharp, NuWave Industries’ technology is starting to catch on in a big way. The company has approximately 800 wells to service this winter alone, largely consisting of expired oil and gas wells throughout Alberta and British Columbia. He explains that every oil company in that region has a specific number of wells they need to abandon each year, so lack of opportunity is not a significant challenge for NuWave. Instead, he says their “biggest challenge” is convincing these companies to try their service for the first time.

“When we first give them pricing, they think, ‘Wow, that’s expensive.’ But when we can do up to nine wells a day versus the conventional way of digging them, it’s a way cheaper price because we can do so many, which cuts down on the time you’re out in the field,” adds Troy. “Especially if there are a hundred or so wells to do. We can go in there and finish them off in a couple of weeks, whereas if you’re digging them, it’s going to take a month or more.”

“It’s kind of an eye-opener once they do see how it works. If you’re doing it the conventional way − let’s say a well and a flow line − you could be there for five to six hours. We can come in there and finish off that site anywhere from one hour to three hours, depending on the size. We’re basically a third of the cost in comparison to doing it the conventional way.”

The pair also cite the environmental and safety benefits of using the NuWave system. In regards to safety, each onsite staff member receives training in First Aid H2S as well as many other Health & Safety programs. Plus, their process is much safer than conventional abandonment methods because it spares workers from having to enter a deep hole that can cave in.

In terms of environmental safety, the company’s process only uses natural water and sand, which are both free of hazardous chemicals. Their equipment is also “all rigged up” with an Emergency Shut Down (ESD) system that automatically shuts the engine down if a leak occurs at any point during the operation − which is unlikely to happen due to the thick insulation in their tubing − thus negating any potential contamination.

One stop shop

In addition to being more cost-effective, safer and environmentally-friendly than conventional well abandonment methods, the NuWave system is also much simpler and tidier. Tim explains the seamless process in detail.

“When we get to the site, we pull up to the well, break the top of the well off, unload our equipment and lower our tool down into the well,” he says. “Once it’s in place, we kick the high-pressure water on. When it gets up to pressure, we turn the sand on. Once it kicks in and we pierce through all the casings, we turn the hydraulics on, which starts rotating the tool down below. Once it reaches full rotation, we shut the sand off and wait a few minutes before shutting the water off.”

“We then pull our tool out and use a hoe to hook onto the wellhead to pull it out,” he adds. “At that point, we insert the capping mechanism − called a centralizer − which is approved by the board. It’s then lowered down into the wellbore with the location welded on it. Once it’s in place, we basically fill the hole in with the hoe and load up all the garbage into the back of our gravel truck and pull offsite. And that’s it − there’s no big hole left.”

“Basically, it’s a one stop shop. If the pipeline’s at the same site, we can do the pipelines as well.”

Although their current system is already significantly more efficient and cost-effective than traditional well abandonment methods, Troy and Tim are constantly seeking new ways to refine their process. They are currently in the planning stages of developing new methods to speed up the extraction of wellheads after they’ve been cut, which will make the overall procedure more efficient and environmentally-friendly.

Beyond that, NuWave Industries aims to expand their services into new markets in the coming years, both within Canada and abroad.

“In five years’ time, I’m hoping that we will have branched out into Saskatchewan and the United States − we’ve been talking with certain companies down there already,” says Tim. “Mexico is another one that we’ve already talked to, and then Europe would be another goal.”

NuWave Industries’ groundbreaking technology will be on display at this year’s Global Petroleum Show.