Digging for the Treasures that no one else sees

Named for success

Gunson Resources Limited derives its name from Mount Gunson, one of the assets that the company had upon its incorporation in 1999. ?At the time, eleven years ago, Gunson’s Mount Gunson copper project comprised 4,000 square kilometres of exploration licences about 100 kilometres south of the world class Olympic Dam copper uranium-gold mine. With several other projects on the go and the implementation of some major new technological advances, Gunson is on the verge of becoming a significant Australian mining company. Located in Perth, Gunson was founded as a company that maintains a focus on mineral exploration and development in Australia. In 2000 it was publicly listed on the ASX, with its main offering being the Mount Gunson copper exploration project, backed by Billiton plc, who put $500,000 into Gunson’s IPO. David Harley, managing director of Gunson, believes that it is only a matter of time- and a short bit of time at that- before really impressive monetary results begin to come in for the company.

According to the Australian Geological Survey, Mount Gunson lies in the centre of the 600 kilometre long Olympic Copper-Gold Province, which contains about three quarters of Australia’s economically demonstrated copper resources. This was an opportunity for the newly formed exploration company that it could not pass up and by predicting the long-term trends of the market Gunson has made a name for itself by acquiring important mineral rights at low costs- cementing its future.

Building on the future

One of the challenges that Gunson has found is that while it may be in the business of trying to predict these markets, investors are often only ready to invest in something they will see quick returns on. Although Gunson has made leaps in its stock price, this is mainly driven by a recent but highly significant rise in the zircon market, after over a decade of low prices.

“Our biggest problem has been that people were expecting very short term returns,” says Harley, “Expectations went up, while at the same time potential investors lost interest when the price of the company’s target commodities were low. We didn’t make bullish predictions to the news and media in order to combat this, but we do need more funding if we want to make the exploration process a shorter term hunt.” Harley and Gunson believe that honesty in the market is often its own reward. With the Mount Gunson project deep exploration it has partnered for sole funding up to $10 million with Xstrata Copper, BHP Billiton having withdrawn from funding in 2003. With this deal Xstrata can earn a 75 per cent interest by spending $10 million on exploration by June 2013, $4 million having been spent to date. It is through prescient investment like this that Gunson has been able to stay on the cutting edge of exploration.

New technology, new opportunities

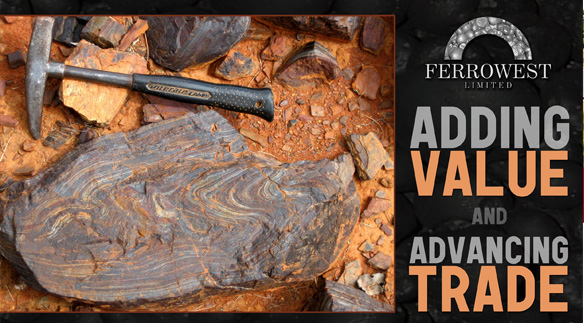

Though the search for a world class copper deposit at Mount Gunson could be viewed as a traditional form of exploration, it is the more recent progress at the Coburn site that really has Harley excited. The project covers approximately 1200 square kilometres of a fossil coastline, and can potentially host a world-class zircon-rich heavy mineral sand field. The price of pure zircon sand is up nearly 50% since early 2010 and this mineral comprises two thirds of the revenue from the proposed mine. “Coburn lies very near the surface, and the rehabilitation process includes completely back filling the mine void as the mine path proceeds along the deposit,” he says. “We have conducted all of our planning and studies in a transparent manner, through a Public Environmental Review and subsequent processes.”

Through their impact studies, Gunson has been able to take note of any ecological effects and address them efficiently. These impact studies are important, and cost a lot of time and money to complete, but the payoff is that the Company knows exactly what it is getting into when it breaks ground on the project. One of the facts that Harley is very proud of is that through Gunson’s reclamation plans it has gathered a huge catalogue of flora and fauna data that will prove very interesting to the academic and ecological community.

Zircon, the most valuable mineral at the site has very particular application in ceramics and for the automotive industry. Used in many car manufacturing plants, chemicals derived from zircon are the key ingredient in the manufacturer’s rust proofing stage. “Being much closer to the giant zircon consuming countries in East Asia than other traditional sources in Africa, the cost for shipping from Western Australia is almost halved as well as the transit time,” says Harley.

Another advantage that Gunson has to draw upon is the collective experience of the Australian mining industry, especially when dealing with mineral sands.? “Australia has such a long history in dealing with mineral sands. In the 1940s one of the first sand mines was Byron Bay, prior to the Second World War. The site is long gone now, but it helped build a specialty market in Australia.” By working with major company Downer EDI’s subsidiary Mineral Technologies, Harley says that the technology can take sand that holds only 1 per cent of a product and concentrate it to 92 per cent. “With this technology we can process 2200 tons of sand per-hour, out of which comes about 25 tons of heavy mineral concentrate per hour,” says Harley.

With new competition in the market, the price of this process that is passed on to consumers is also reduced. “This project has the main revenue generating commodity of zircon, which we find in the fossil beach-dune sand deposit of the area. Within the deposit the most common valuable heavy minerals are of titanium dioxide, which are mainly used in making pigment for paint.” China, he says consumes about 40 percent of the zircon produced in the world. Other than in the auto-industry, the zircon at Coburn can be used in other manufacturing processes such as the creation of glaze for ceramics and sanitary ware. “Zircon provides the hardness and opacity of the outer layer of ceramics and creates resistance to corrosion – and, of course, the nice shine you get from the product,” he says. “We have a lot of interest from possible investors and partners in the Asian market- where construction of offices and housing has increased the consumption of ceramic tiles and sanitary ware. Also, Japanese auto companies don’t like broadcasting their need for zirconium chemicals in rust proofing but it looks like this practice will soon spread to the US which will massively increase the consumption. The Japanese and Koreans have seen that this rust proofing works better than anything else.” ?The other emerging use for the zircon in the sands at Coburn is in making zirconium containers for nuclear fuel rods, as well as hazardous waste containers. Zirconium metal has been appropriated for this use because, as Harley says, “it won’t melt, has high resistance to corrosion and is a radiation shield, and other materials just don’t hold up the way zirconium does.”

With new technologies emerging that require zircon and titanium dioxide minerals to operate that Gunson can supply, Harley estimates that Gunson will be looking at annual revenue of 100 million dollars. “According to credible industry studies there will be a 30 per cent supply deficit of zircon by 2015, and in the next 4 years the price is expected to rise by another 30 per cent,” says Harley. Gunson Resources may not be mining gold, but it is sitting on a gold mine of minerals and important industrial ores.