Evolving into a World-Class Operation

Salinas Construction excels, diversifies amid ever-changing times

Â

The workplace philosophy for John Salinas II largely revolves around just two words.

World class.

He strives to hire world-class employees. He aims to provide them with world-class working conditions and resources. And when those things are combined, he expects them to deliver his customers a world-class end product – regardless of size, shape or circumstance.

It’s a mandate he knowingly and willingly took upon himself when he took over as a third-generation leader at his family’s now 35-year-old business, Salinas Construction, in 2007.

“It’s obvious pressure,†he said. “One thing I was told in grad school is that 99 percent of all third-generation companies fail, and that I shouldn’t even look at this as an opportunity; I should look far and wide to find a different industry as a whole to get into.

“But my personality is that that’s more of a challenge than it is a gospel.â€

Indeed, his mere presence at the company is the latest stage of a prolonged evolution that began when his grandfather and father, Juan Salinas and John Salinas, founded the business in 1979, not long after Juan Salinas had moved the family from Corpus Christi, Texas to the Pacific Northwest.

Juan Salinas had work experience but no high school education. John Salinas partnered with his father upon completing high school and did not attend college. By contrast, John Salinas II earned a graduate degree in business before purchasing a majority share of the company and becoming its president.

“The massive change has come from just being a contractor, a constructor of sorts, to more of a contracting company,†he said. “Your overhead staff began with hiring an estimator, and then that led into hiring an accounting staff and that led into hiring project managers. That’s really where the big evolution in the industry has come.

“Now it’s more contract law than it is necessarily how well you can build something.

“That’s kind of changed our train of thought and it’s kind of changed what each person brought to the table. I viewed this as a large change in the industry, going more into contracting, making sure our paperwork is very tight and that we are complying with all contract language and that we are able to service clients that are very, very, very stringent.â€

The company maintains a 12-month rolling average of 70 employees, which accounts for the cyclical nature of the work – which can boost the workforce in excess of 100 employees during busy times in the summer, and drive it down as low as the 40s when things are slower from November to March.

A main administrative headquarters and a main operations area are about 10 miles apart in the northern Seattle suburb of Mukilteo, Wash., and a recent aggressive push into the Hawaiian market could soon lead to a permanent brick-and-mortar presence over there as well.

Between 90 and 98 percent of the company’s revenue is generated from government/public works agency projects. Two of the largest clients over the last few years, Salinas said, have been the U.S. Army Corps of Engineers and the U.S. Navy; while other work is done on the state level with localized departments of transportation, alongside smaller but more frequent projects with city-level agencies.

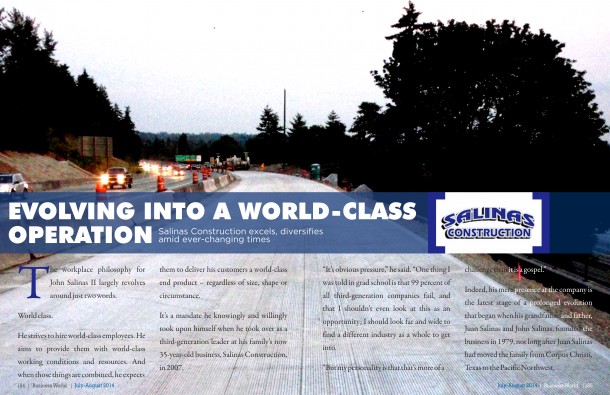

“It’s a fairly niche industry to do concrete slip-form paving, especially in the greater Pacific Northwest,†Salinas said, while labeling four in-state entities as competitors within Washington and two more in Hawaii. “A lot of stuff is not done in concrete, so the number of competitors is obviously different than that of asphalt, because a lot of work is done with asphalt as opposed to concrete.â€

Technology, personnel and experience are his separating elements from those in the concrete field, he said, and the company was first in the state to incorporate the use of stringless paving on projects – which allows design files to be analyzed for ride-ability before completion, as ensures targeted levels of pavement thickness from the subgrade up by using 3D machine control.

Innovation, plus a particularly close eye on the bottom line has equaled success.

“We run a very tight operation relating to our paving,†Salinas said.

“Ninety percent of the stuff we bid is low-bid unit priced contracts, so a lot of it is just based on how efficient can you bring your operations to arrive at a best value for a government agency. How can you get the bottom line that they’re looking for?â€

Among the most recent projects have been a large apron at Joint Base Lewis-McChord just south of Tacoma, at which Salinas workers completed 40 acres of concrete paving; a thinner concrete apron around a new hangar at Fort Wainwright in Fairbanks, Alaska; and a role as part of the design team for replacement a mile of full-width interstate on Interstate 405 in greater Seattle.

As part of the latter project, workers laid 6,200 cubic yards of concrete over two24-hour weekend closures, a task Salinas conceded afterward was the product of both acumen, and swagger.

“We are confident, sometimes maybe to a little bit of a fault,†he said.

“Concrete paving, for what we need to do, needs to be world class. It needs to stand out on its own. And it can be done. It’s just how well can you plan for both the foreseen and the unseen. We’re confident that we know what we’re doing, that we have the technology in place and that we have the people in place to compete with the best companies on the planet. But it has bitten us a couple of times, trying to be a little too aggressive.â€

That admission notwithstanding, it’d be unwise to expect the approach to change anytime soon, as the company moves away from being simply a high-end niche subcontractor to a new, expanding role as a government-servicing prime contractor.

“We can be one of the finest concrete paving operations in the world for servicing airfields. We don’t have the highway infrastructure around here to become a raw production mainline highway paving company, I believe, though, that we can service any airfield on the planet with the equipment that we have and the personnel and technology that we have,†Salinas said.

“That’s where I hope to see the business – with a solid foundation in slip-form paving for airfields and highways around the Washington, Alaska, Hawaii areas, with various ventures into other states. And then the second part of the company being a bona fide government prime contractor.â€

AT A GLANCE

WHO: Salinas Construction

WHAT: Third-generation heavy highway and airfield concrete construction contractor that’s been working in both the private and public sectors since its inception

WHERE: Corporate headquarters in Mukilteo, Wash.

WEBSITE: web.SalinasConcrete.com