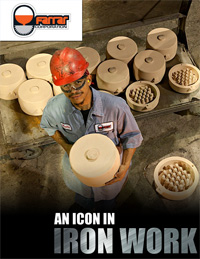

An Icon in Iron Work

In respect for the significance of the craft as well as the craftsman, blacksmiths have not only long served as subjects of fantasy and fable, but also as symbols of power and strength to many civilizations. Examples include Isaiah’s Old Testament reference to a blacksmith in order to make a point about divine mastery and strength. Then there was Temujin (better known as Ghengis Khan) whose name meant “Man of Iron.â€Â The Duke of Wellington who defeated Napoleon was dubbed the Iron Duke and in the modern era, former British Prime Minister Margaret Thatcher was called the Iron Lady. To this list, add the name of Farrar, a derivative of the Latin word “Ferrum†which simply means iron. In Kansas, Farrar is the name of a family with a distinguished legacy in metal forging and foundry services, yet is also the name of a corporation with an iron-strong reputation for much more.

Though it began life more than 80 years ago as a blacksmithing enterprise nestled amidst the grain fields of Norwich, Kansas, the Farrar Corporation exists today as a dynamic single-supply-source for ductile iron casting, machining, heat-treating and assembly services which capably cater to a wide range of industrial and manufacturing needs. Adding considerable credence to its corporate claim as “So much more than just a foundry,†Farrar’s engineering and production expertise is essential in everything from the manufacturing of heavy trucks and medical devices to implements of aerospace as well as tools of terra firma such as lawnmowers. Farrar’s materials can also be found among critical applications in which human lives both depend and demand functional strength, such as the braking mechanisms used by elevators or the metalwork vital to the integrity of bridges, elevated roadways and other construction. Farrar Corp. Sales and Marketing Manager Rusty Rainbolt says his colleagues not only take great pride in their ability to serve in the manufacturing of such applications, but they also take great care to deliver on the quality that is required, and that’s a commitment as heavy duty as the ductile iron Farrar is esteemed for supplying.

Metal Casting Marvel

In an industry that has experienced considerable consolidation and acquisition by investment firms, Farrar still functions as one of the few family-owned operations in the industry. Rainbolt explains how the company got its start by E.C. Farrar, a 1930’s era blacksmith who grew the business by installing furnaces and producing material essential to the repair of farm equipment. By the early 1940s, Farrar had grown the business into one of the largest blacksmith shops in the region. The company would undergo more major transition after building the green sand foundry in 1967. That move allowed the company to begin producing its own castings, and within five short years, the foundry operations accounted for almost half of all Farrar’s business. Under the leadership of E.C. Farrar’s son, business grew to such extent that the company discontinued its own product line to focus solely on providing build to print products. Since this time, Farrar has become proficient in pouring all grades of ASTM A536 Ductile Iron, in castings from 2 pounds to 70 pounds and production runs of 100-100,000. In the early 1990’s, E.C.’s grandson Joe Farrar added the capability to produce austempered ductile Iron as a side item to their standard ductile iron grades. An ISO 9001:2008 quality certified company, Farrar’s capabilities today encompass the range of technical engineering consulting, casting design, pattern design, production, heat treating, machining, painting and assembly.

Farrar’s foundry operations allow for the processing of nearly 40 tons of melt per day. State-of-the-art CNC operations allow for all manner of turning, milling, boring, facing, drilling and tapping. Those capabilities include turning up to 27 inches diameter, milling up to 40″ x 40″ x 36″, gear cutting up to 10″ diameter, as well as fixture design, fabrication and painting. As a manufacturer of castings with in-house competence in machining, Farrar also provides a range of assembly services which, for customers, connotes to greater convenience, quality control and cost savings. Farrar is a source of more than 1,700 customized parts for more than 70 manufacturers.

Transitioning into a leading national supplier of services and solutions has required Farrar to continually reinvest in top-of-the-line equipment, expert staff and expansive operating space. Beyond the initial plant in Norwich, Farrar has a second machining plant, allowing for some 50,000 square-feet of production space in Manhattan, Kansas, today. Farrar is a company which has underwent transformation of increased services and skills in every era, yet as Rainbolt says, that which has intently remained unaltered has been the family values of professionalism, quality and accountability. Joe Farrar represents the third generation of family leadership.

Rainbolt says the ability to increasingly build upon its core expertise while also increasing its delivery efficiencies and impart value-added services to its customers has been critical to Farrar’s strategy for growth. And that’s not merely paid off for the company, but their customers as well. The benefits posed through working with Farrar has been particularly evident in projects that have included San Francico’s Bay Bridge as well as the Mike O’Callaghan–Pat Tillman Memorial Bridge, a 1,900 foot bridge spanning Hoover Dam (not to mention a 900 foot chasm) making it the seventh highest bridge in the world. In these projects, post tensioning systems were used to hold steel cable within the concrete to keep the structure compressed. This necessitated the use of up to 80-pound anchor heads and 40-pound bearing plates, each with a diameter of 15 inches. The anchor heads and bearing plates had to be cast in 80-55-06 ductile iron or Grade 3 ADI, whose properties make it as strong, or significantly stronger, than comparable steel while being easier to manufacture. In this instance, Farrar was not only a vendor of choice due to its ability to produce the components, but its ability to produce the material to the desired elevated specifications, all tested for soundness and certified through rigid quality assurance systems. Also, by being able to machine the castings and perform assembly (thereby delivering a more complete end product for the project) the contractor was spared from delays, costs and headaches which typically arise when having to work with multiple service suppliers to acquire one line of product.

Conscientious Collaboration

Farrar’s approach to cooperative partnerships has also resulted in benefits that contribute to quality of the environment and quality educational opportunities. On the environmental front, Rainbolt explains how Farrar developed a partnership with a furniture manufacturer allowing it to source residual scrap steel the company would otherwise discard and use it as an ingredient in their iron. In so doing, the furniture manufacturer is now generating no waste and thereby reducing its carbon footprint.

In terms of education, Joe Farrar (along with his wife and children) is a dedicated alumnus of the Kansas State University which developed such initiatives as the Manufacturers Learning Center and the Advanced Manufacturers Institute (AMI). Farrar formerly served as an advisor to these endeavors which served as a resource for small to medium-sized manufacturers throughout all of Kansas, helping small companies connect with support in technical research, product design, product testing and process improvement. They also provided critical, hands-on training to engineering students. Farrar has routinely consulted with university research teams designing innovations and applications for Formula 1 competition, as well as the Mini Baja and the ¼ scale tractor. The research teams demonstrated how using austempered ductile iron can be used (particularly in rear suspension frames) to achieve the desired accommodated by traditional metals, yet is much lighter in weight. Rainbolt says Farrar’s role has not only helped students acquire a better understanding of engineering processes, but these advances also help industry professionals gain a better understanding of the benefits of ductile iron in the manufacturing process.

Advancing education and developing a highly-trained workforce to fulfill tomorrow’s demands of industry isn’t, however, the only aspect of Farrar’s future thinking. Rainbolt says the company is continually focused on providing value to its customers, and that’s not just mere talk, but the fundamental company mission. Rainbolt says the company can be anticipated to further build upon the work it is providing for current customers. He also notes that the company is encouraged by opportunities in aerospace, as well as the manufacturing of medical devices and alternative energy. He believes these industry sectors represent significant areas of future growth for Farrar.

Through its dedication to quality manufacturing standards, its willingness to readapt capabilities and efficiencies to bring value to customers, and by adhering to family-honed values of teamwork, integrity and experience-driven expertise, look for this machinist and metal casting manufacturer to increasingly cast a shadow of operational service and success throughout the industry.

For more information, please visit their website at: Â Farrar Corp.