One of a kind

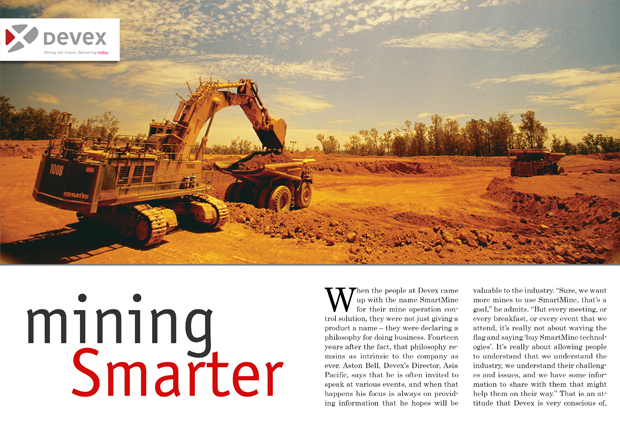

The suspended dump bodies that Duratray International manufactures are truly unique in their design, says the company’s General Manager Mining, Luis Rojas. And when he says they are unique, he really, authentically, means it. “There’s no one else like us out there,” he says confidently. “Lots of companies sell trays, but they are all the same. They might look different to some degree, or have different designs, but they’re all steel and the floor is steel. With the Duratray you have a unique product.” The Duratray difference Rojas is referring to is its suspended rubber mat, which provides a plethora of benefits a steel floor cannot. These benefits consist of, but are not limited to, being lighter in weight, requiring lower maintenance, reducing carry back, offering resistance to extreme abrasion, reducing noise, and offering lower shock and vibration to the truck and its operator.

Duratray as a company has a long history. Their product was first invented by a Swedish company who promoted the product in Europe and some parts of USA. That company eventually sold the product to Pacific Dunlop, who in turn developed it further in Australia and brought it to Canada. In 2001, however, Dunlop began selling off some of their portfolio, including their suspended dump body. That offer was extended to a number of companies, but it was the Chilean company Conymet that ultimately scooped it up. Conymet, at the time, was led by its founder Manuel Medel Sr, but the responsibility to lead the new acquired company fell in the brothers Marco and Manuel Medel. “That’s how Duratray came to be as a company,” Rojas says. “And in the last eight or nine years we’ve turned it around quite significantly.”

Rojas himself is Chilean born, having immigrated to Australia in 1975. He has a degree in computer information technology and business management. Prior to working at Duratray, he spent time at a number of larger, corporate companies. When he was offered a management role at Duratray, he accepted and set about revamping the company. “I established a transformation program that took us to the next level,” he says. “I’ve been with the company now for close to five years, and the strategies I put in place back then have been quite successful.”

Trends and challenges

One trend Rojas has observed since joining the tray manufacturing industry is the fierce competition. “Some of our key competitors worldwide are the big boy equipment sellers, like Caterpillar, who have the biggest market. We’re continuously running into them – or let’s put it the other way around, they’re running into us,” he says. And it is not only them whom Duratray find themselves constantly tendering against, or fighting with for clients. “One of the things that’s happening in the tray or dump body industry is there’s a lot of companies now manufacturing trays, all the way from South Africa, Peru and Chile. In Australia there’s probably about seven or eight alone.” The key to staying competitive has changed, as well. Five or six years ago, he says, the most important feature for a tray was a low maintenance cost- nowadays; the lighter the better. “Our objective now is to do that, to become lighter,” he says.

“We’re normally lighter than conventional trays from Caterpillar or Komatsu and the other standard bodies out there, but now we are being challenged by a lot of the ultra light trays,” Rojas says. “One of the biggest challenges at the moment is to ensure that we reduce that weight further. Not only do we need to have all the benefits that we provide from a perspective of vibration, impact, noise and so many other things – we have to have that, plus we also have to be light.” He says they are already engaging with some contracting companies to help redesign the Duratray in order to achieve this. Lightness is the future, and Duratray is prepared to embrace it. One challenge they managed to avoid was the effect of the global financial crisis. “We prepared ourselves for the worst, and it wasn’t that bad. We had a lot of purchases through that year. Sometimes I am embarrassed to say that,” Rojas jokes. “But we did fairly well.”

A dynamic design for a?dynamic company

Again, Duratray’s product is the only one of its kind on the market. “Because of that, we can provide quite a list of benefits straight away, due to our design. There’s no one else out there that can give you impact shock absorption, or a lack of noise. There’s no one. Steel trays make a lot of noise, a lot of impact, a lot of vibration,” reports Rojas. These key advantages are especially relevant in areas such as Hunter Valley in New South Wales, where the mines are located very close to communities. By using Duratray’s suspended dump body, they are able to reduce a substantial amount of noise.

Rojas says Duratray is not as large as some of the other companies he has worked with, but if anything, that is a good thing. “I was bored with big companies, where I spent a lot of time in committees and meetings, and making decisions with groups of 10 to 15 executives. One of the reasons I moved into Duratray was that it was a fairly dynamic company where decisions were being made really quickly,” he says. The employee count at Duratray in Australia, Rojas says, amounts to somewhere between 50 to 70 people. “It’s definitely a smaller company, and we have got a fully dynamic team and a fully dynamic way of doing things. It allows us to basically grow and establish things quite quickly, which is one of the key reasons I enjoy the job. We’re not involved in as much bureaucracy.”

For Duratray, maintaining their relationships with employees’ means challenging them. “The mining world is continuously changing,” Rojas says. “It’s changing quite dramatically out there and it keeps everyone on their toes, so to ensure that we can keep up with the market we need to ensure our people can keep up with the market.” They achieve those assurances through techniques like conferences and technical workshops. He says it all comes back to that dynamic aspect he values. “I think that keeps our workforce alive and vibrant,” he says.

Growing through feedback

In the future, Rojas sees Duratray becoming a much bigger company than it currently is. “We’re continuously growing as a company. I see Duratray as having a much more innovative design, but in a way where we’ll continue to be a unique product. We’ll be lighter, we’ll be more competitive.” Additionally, the company will be expanding their portfolio. They are already evaluating other products towards that end – like a rail cart, for example. “I see Duratray having a band of portfolio products that are going to be similar in uniqueness and very beneficial to the mining world.”

Another important aspect of the company’s growth, according to Rojas, is client feedback. “There’s no doubt that Duratray as a company is continually growing. One of the key objectives we have going forward is learning from some of our mistakes, and learning from feedback the client provides. Due to that feedback we’re making changes to the way we develop. I think definitely the future in the alignment of the product is due to client feedback rather than our decisions of what we think are best. We’ll leave it right to the mines,” says Rojas. oThe suspended dump bodies that Duratray International manufactures are truly unique in their design, says the company’s General Manager Mining, Luis Rojas. And when he says they are unique, he really, authentically, means it. “There’s no one else like us out there,” he says confidently. “Lots of companies sell trays, but they are all the same. They might look different to some degree, or have different designs, but they’re all steel and the floor is steel. With the Duratray you have a unique product.” The Duratray difference Rojas is referring to is its suspended rubber mat, which provides a plethora of benefits a steel floor cannot. These benefits consist of, but are not limited to, being lighter in weight, requiring lower maintenance, reducing carry back, offering resistance to extreme abrasion, reducing noise, and offering lower shock and vibration to the truck and its operator.