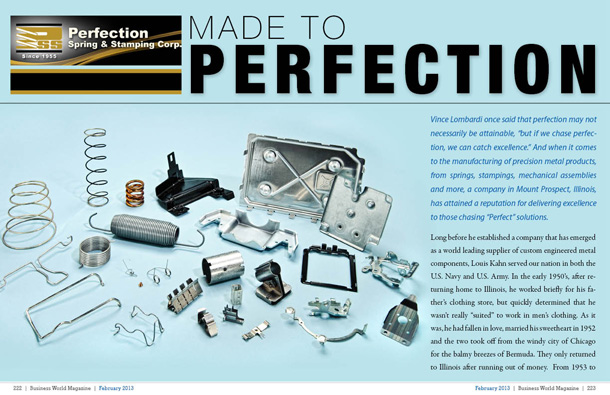

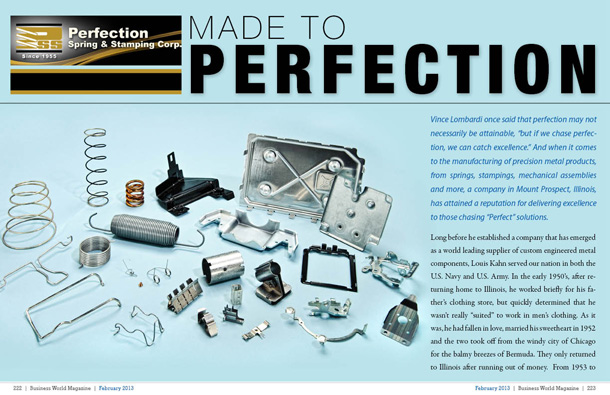

Vince Lombardi once said that perfection may not necessarily be attainable, “but if we chase perfection, we can catch excellence.†And when it comes to the manufacturing of precision metal products, from springs, stampings, mechanical assemblies and more, a company in Mount Prospect, Illinois, has attained a reputation for delivering excellence to those chasing “Perfect†solutions.

Long before he established a company that has emerged as a world leading supplier of custom engineered metal components, Louis Kahn served our nation in both the U.S. Navy and U.S. Army. In the early 1950’s, after returning home to Illinois, he worked briefly for his father’s clothing store, but quickly determined that he wasn’t really “suited†to work in men’s clothing. As it was, he had fallen in love, married his sweetheart in 1952 and the two took off from the windy city of Chicago for the balmy breezes of Bermuda. They only returned to Illinois after running out of money. From 1953 to 1954, Kahn made a living from the selling of canned food goods, but enrolled in a trade school to learn the art of tool & die making. It would take another year, but upon graduation, he secured $5,000 in capital and with support from his Aunt Fannie, opened a new business. Equipped with faith in his capabilities, determination and a healthy measure of confidence, he named the enterprise “Perfection Spring Manufacturing Company.” Yet, on the equipment side, he had one coiling machine and a well-used four-slide machine which he put in his garage and went to work. His wife, Barbara, helped run the machines during the day while Kahn drove around trying to drum-up clients. Aunt Fannie handled bills, invoices, mail and book-keeping, but wasn’t too over tasked because the company didn’t make any money for the first six months. Kahn wasn’t the kind of man to give-up without a fight, and he doggedly pursued business, soon securing his first customer in a garage door company. As much as success breeds success, other customers followed and by the end of that first year, the company had obtained a joyous $300,000 in sales.

The revenues grew, right along with the company as Kahn invested in new equipment, new staff and the opening of a new factory. Through it all, Kahn practiced face-to-face business with clients, securing agreements with the shake of hand, an aspect of business he once said that he is sad to see as missing from so much of business today. In the years that followed, Kahn encountered many challenges in the form of economic downturns and large customers going out of business, but battled through and beyond to create what today is recognized as Perfection Spring & Stamping Corp. – a leading global supplier of precision metal-formed components. Louis Kahn once credited his success to his reliance on four critical values: Integrity, honesty, hard work and persistence.

These values are still effectively embraced by the company today which continues to perfectly adhere to the principles of professionalism and product quality, which is not just a routine aspect of everyday operations, but something in the way of a personal mission to maintain a legacy, at least, that’s the way Louis Kahn’s son, Joshua, sees it.

As the company’s Executive Vice-President and Vice-President of Sales & Marketing, Joshua Kahn says Perfection Spring and Stamping supports customers by providing the most innovative and cost-effective engineered solutions, prototypes, components and assemblies. This enables their respective business partners to achieve superior financial results and quality growth. In so doing, the company has continually cultivated long-term partnerships with companies around the world in a variety of industries including, medical, consumer electronics, electrical, appliance and automotive markets, just to name a few.

“We have provided engineered solutions of metal products and assemblies to meet their most demanding applications,†says Kahn.  “We have brought three primary areas of manufacturing under one roof. We have our own set of competitors and customers for each area.â€

Customer Interaction

Perfection Spring & Stamping Corp takes great pride on customer involvement every step of the way, including the early stages of design and engineering. Their engineering and sales teams collaborate with customers to design the most cost-effective method of manufacture to meet their highest quality standards and engineering tolerances. “We like to partner with our customers in the design phase and the planning stage to work out cost up-front,†Kahn says.

This desire to meet and exceed their clients’ expectation is something that sets them apart from other precision metal companies. “We align ourselves with companies seeking the finest in metal stampings, springs, wire forms and assemblies, taking advantage of these three primary metal forming specialties,†he says. “We’re able to match the requirements of the customer by building it in the best work center to achieve the highest quality at the lowest cost.â€

Their manufacturing capabilities include large and small custom metal clips, contacts, brackets, covers, heat sinks, connectors, fasteners, shields, retainers, and connectors, as well as wire products such as torsion, extension and compression springs. “Our expertise in metal forming even the most complex parts and components is unique. We produce custom metal stampings, springs, and wire forms – from almost any ferrous or non-ferrous raw material that meets a wide-range of specifications and standards.â€

Whereas other companies offer just one area and type of manufacturing, Perfection Spring can offer several to tailor each individual project to fit a customer’s need. From punch press to fourslide, coiling to assembly, Perfection is a single source supplier for of their customers’ metal-forming requirements.  “By bringing these areas under one roof, we believe we’ve been able to offer a wide-variety of metal components to our customers. It’s a sort of a one-stop-shop,†he says. “In doing that, our customers are able to reduce their supply base by sometimes two.â€

Their ability to supply stampings (Up to 600 ton max. capability), springs (compression, extension, & torsion), wire-forms and assemblies that allow customers to reduce their vendor base by two or even three companies. “Depending on the volume, type of product, the duration of their program, we can match the manufacturing type that meets all the requirements.â€

Â

FIVE FUNDAMENTAL STRENGTHS

Perfection Spring is further distinguished from its competitors through its flexing of five strengths.

Kahn identifies the first as financial stability – “We remain profitable and sustainable even through the current economic downturn, in part though our market diversification and our conservative philosophy guiding the way we have done managed our business since 1955,†he says.

The second is design and engineering excellence. “We continue to offer innovative cost-reduction options at the design stage and value-added/value-engineered cost savings for our customer’s current products.†The next strength is their flexibility to adapt and reinvent. “We listen to our customers and add systems, processes, equipment or facilities constantly to meet the needs and requests of our customers,†he explains.

Delivery and service make up the fourth strength. “While these key indicators are a ‘given’ today, we track, monitor and implement changes to always improve our goals as we strive to improve in everything we do.â€

The last of the five strengths, perhaps the most important, is quality. Their commitment to quality is backed up by third-party certification to world-class quality standard ISO/TS 16949:2002. “We offer the global OEM market quality distinction in manufacturing, innovative and engineering,†he says.

World Market

Since the United States is currently considered a low-cost country, Perfection Spring & Stamping Corp’s exports to the world market have significantly increased. At the moment, they serve North America (NAFTA), the European market and Asia. Shipping destinations include Canada, Mexico, China, Korea, The Philippines, Taiwan, France, Germany, the Czech Republic, Israel, Malta and India, among others. “Our exports continue to grow as the global market sees the advantages Perfection can offer,†Kahn explains.

Looking ahead to the longer term, one of the strategies for Perfection Spring & Stamping Corp is to expand the existing list of countries they export to by adding new markets they’ve never been in before. They will also take their products and services and branch into new industries “we’ve never been in before.â€

They recently expanded into the sustainability market taking on projects for solar energy, electric cars and renewable energies. In addition to new markets, they are continually upgrading their processes and equipment, and will continue to do so moving forward. “We are always advancing our own manufacturing capabilities with new technologies and markets. I think the people that don’t are the ones who are left behind,†says Kahn.

“The whole idea is to make us better, smarter, faster and cheaper. Our customers call it ‘The Perfection Advantage.’â€