May 2013

| Business World Magazine | 189

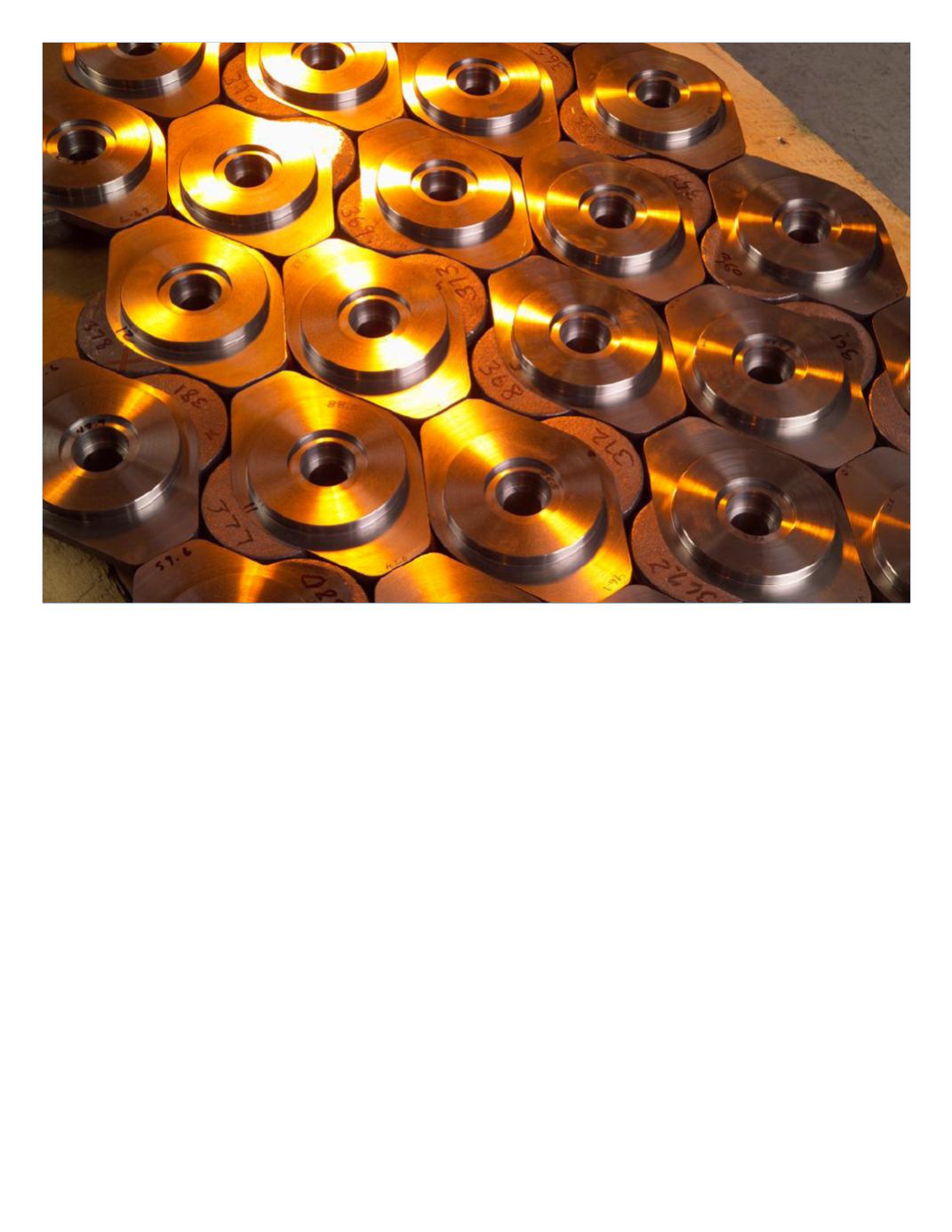

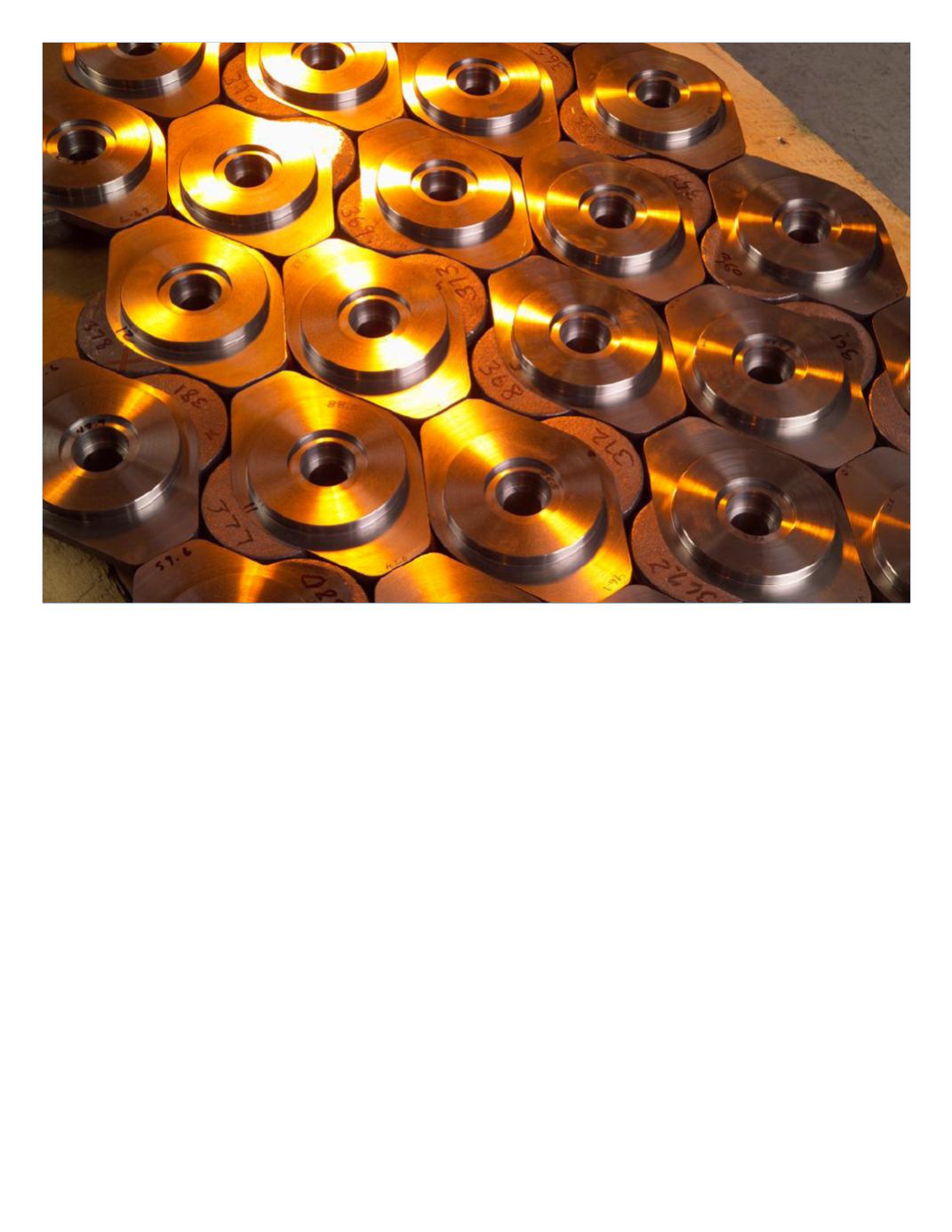

been critical to Farrar’s strategy for growth.

And that’s not merely paid off for the com-

pany, but their customers as well. The ben-

efits posed through working with Farrar has

been particularly evident in projects that

have included San Francico’s Bay Bridge as

well as the Mike O’Callaghan–Pat Tillman

Memorial Bridge, a 1,900 foot bridge span-

ning Hoover Dam (not to mention a 900

foot chasm) making it the seventh highest

bridge in the world. In these projects, post

tensioning systems were used to hold steel

cable within the concrete to keep the struc-

ture compressed. This necessitated the use of

up to 80-pound anchor heads and 40-pound

bearing plates, each with a diameter of 15

inches. The anchor heads and bearing plates

had to be cast in 80-55-06 ductile iron or

Grade 3 ADI, whose properties make it as

strong, or significantly stronger, than com-

parable steel while being easier to manufac-

ture. In this instance, Farrar was not only a

vendor of choice due to its ability to produce

the components, but its ability to produce

the material to the desired elevated specifi-

cations, all tested for soundness and certi-

fied through rigid quality assurance systems.

Also, by being able to machine the castings