174 | Business World Magazine |

May 2013

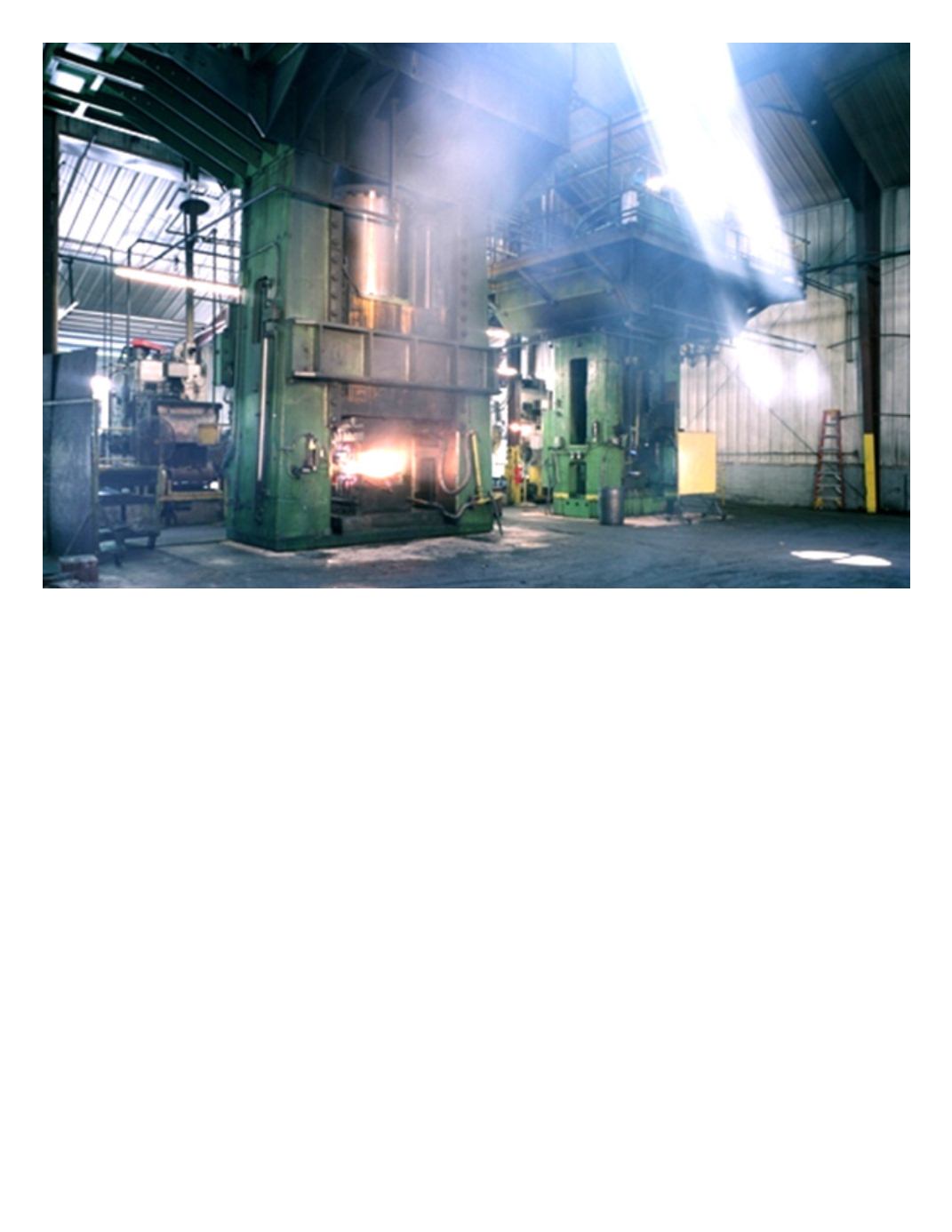

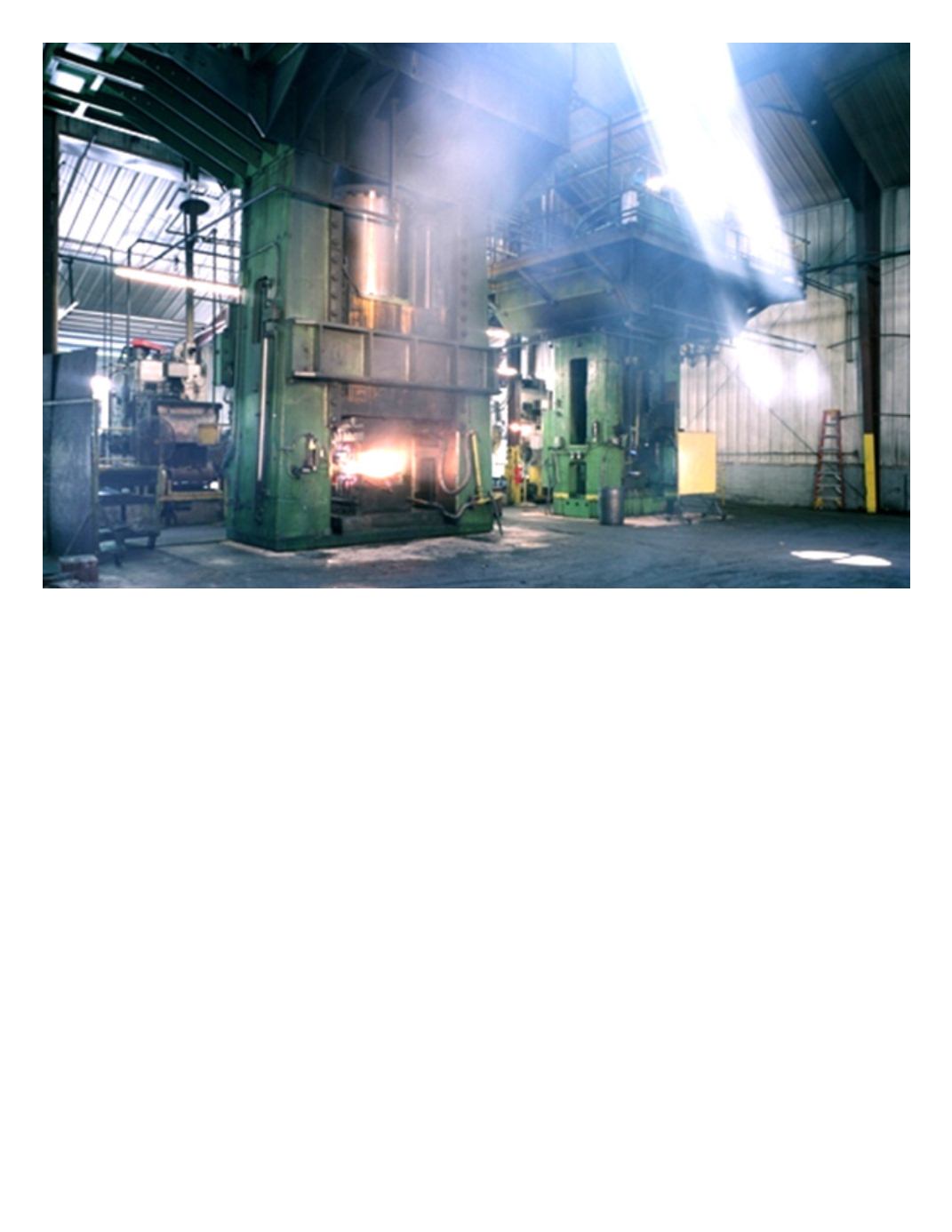

Over the last six decades, incredible advance-

ments have been achieved in the designing

and engineering of aeronautics, be it in the

form of fixed-wing aircraft and jet engines to

helicopters, nuclear propulsion systems and

more. The emergence of such mechanized

marvels has been supported by the vital ef-

forts and expertise of a dynamicmetal forging

company known as Consolidated Industries.

Operating from a 15-acre site in Cheshire,

Connecticut, Consolidated Industries is a

producer of custom-designed, closed-and-

open varieties of die forgings essential in the

manufacturing of some of the world’s most

sophisticated technical innovations. Consol-

idated Industries’ components can be found

among the applications on Sikorsky “Black-

hawk” and Boeing “Chinook” helicopters,

Lockheed’s C-130 “Hercules” and Northrop

Grumman’s E-2C “Hawkeye” - just a few ex-

amples of their highflying handiwork. Con-

solidated produces fuel system valves, as well

as the elbows, blades and vanes for aircraft

engines. They forge the shafts, fins, adapter

collars and controllers utilized in missiles.

They make the rotor components for heli-

copters, the landing gear components in air-

craft frames and the stainless steel blades and

vanes necessary for the generation of power.

The client list of Consolidated reads like a