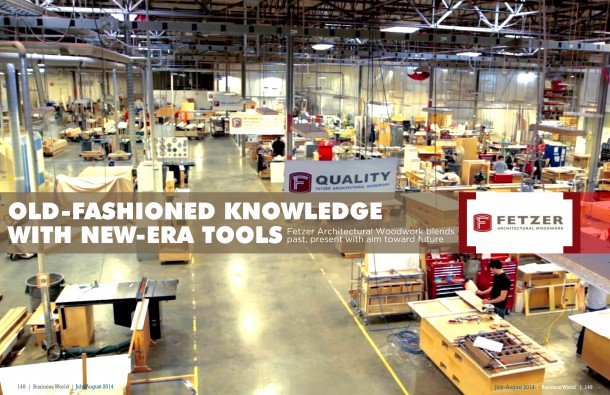

Old-Fashioned Knowledge with New-Era Tools

Fetzer Architectural Woodwork blends past, present with aim toward future

The phrase “architectural woodwork†conjures a vivid image.

A dedicated, hands-on craftsman with years in the trade, working attentively on every last detail while creating a visually striking product for an end-user.

That’s the way it was at Fetzer Architectural Woodwork when things got started back in the earliest days of the 20th century. And, while he concedes there have been a few technological improvements in the subsequent 105 years of business, that’s the way Joseph Wixom wants it today, too.

“There are machines that do many things that men used to do, in some cases even as recently as 15 or 20 years ago,†he said. “However, in architectural woodwork, the craftsmanship that is required to reflect in the wood what our clients and these architects desire, it takes tenured skill.

“This isn’t a three-year apprenticeship and a two-year journeyman training program.Our most seasoned carpenters on the shop floor have been with us 30 and, in some cases, 40-plus years.â€

Not surprisingly, the company celebrates its history with an equal amount of reverence.

It began in 1909 as a small cabinet shop founded by Kaspar Fetzer in downtown Salt Lake City and has subsequently grown into one of the country’s largest millworkers, whose fingerprints can be found on substantial projects across the United States and in retail-centric products in China and New Zealand.

A new corporate logo was commissioned to recognize the 100-year birthday in 2009 and an element of that new symbol was maintained on subsequent logos through 2013.

“It’s celebrated in everything we do and everything we recognize within our company,†Wixom said. “In our entire sales approach, in our documentation, in our processes – both in what people see and in what we do behind the scenes –everything is guided by that historical precedent.â€

Fetzer, circa 2014, is operated from two primary manufacturing facilities located about five miles from one another in suburban Salt Lake City. The architectural-specific building went up in 2005 and covers 120,000 square feet with cutting-edge woodwork equipment. The second building, which covers about 90,000 square feet, is home to quick-turnaround retail work.

The combined workforce ranges from 215 to 220 at any given time, Wixom said. All manufacturing employees are part of a regional carpenters union, he said, which enables the company to flex specific skill sets between the two facilities to meet demand for a particular product.

Fetzer’s workload is driven by two markets – high-end retail store fixtures and the build-outs of massive projects like law firms, libraries, performing arts centers and corporate office buildings. The retail fixtures space is impacted by both the economy and the calendar, while the architectural millwork provides a more predictable revenue stream.

The two-pronged approach, as it turned out, allowed Fetzer to sidestep a significant impact from the worst days of the recent Great Recession. It’s also ensured what’s been a prolonged stretch of demand for the company’s work, because it remains one of the few shops in the country with the size, scope and capacity to serve those dual markets.

“The people who spend the money for our product weren’t necessarily the people who stopped spending money,†Wixom said. “There’s still plenty enough demand that we’ve been able to maintain a steady growth. And that growth is simply because the markets have grown.â€

In-state architectural projects on which the company’s work is prominently featured include both a new federal courthouse and a new six-story building that houses the Kirton McConkie law firm in Salt Lake City, as well as the remodeling of the Brigham Young University law school in Provo.

Outside the state, Fetzer’s work is visible at Levi’s Stadium – the new home of the NFL’s San Francisco 49ers – and on a tower at the Fordham University law school in New York City.

Meanwhile, Fetzer’s highest-end retail clients request products that can subsequently be found in those clients’ stores throughout the world, but the majority of its overall business comes from U.S.-based interests.

About 60 percent of the work is for general contractors on architectural projects, while the remaining 40 percent is the direct-to-end-user retail work. It’s a fairly steady ratio, Wixom said, but some extreme years have seen the architectural projects side handling nearly 100 percent of the load – and that side’s percentage has rarely dropped below 50 percent of total revenue.

“The retail side is where we can experience rapid growth and occasional shrinkage,†he said.

In terms of its competition in those spaces, Wixom boils Fetzer’s edge down to a single word:

The company embraced lean manufacturing principles when it moved into its newest building in 2005, he said, and the dedication to a concept that considers expenditure of resources for anything other than the creation of customer value as waste is what’s fueled the progress of subsequent years.

“Our lean processes in manufacturing allow us to our footprint effectively with a crew of 55 guys, as much as can use it with a crew of 125 guys on the shop floor,†Wixom said. “It’s our ability to ramp up or ramp down – depending on the customer’s needs and the type of machinery required to process the product that they require – and then our organization in our up-front process.

“Our shop drawings, we believe, reflect as much if not more detail than anyone else in our competitive industry. Though we strongly feel we have the best carpenters in the world on our shop floor, we still like to give them what we affectionately refer to as Lego drawings. We take the guesswork out of those drawings so that their craftsmanship can show in the finite details.â€

Still, no matter how much the front end may change, the back end remains a hands-on proposition.

In fact, Fetzer has eschewed a trend toward automating the finish process with a rolling-line system that’s become popular in the industry, in favor of a throwback to its Theodore Roosevelt-era roots.

“It’s the control you get,†Wixom said, “when you have experts with 30-plus years of finish experience laying that finish down and understanding the benefits of a hand finish and really giving the attention required to meet the customer’s expectation from the samples that we’ve represented.â€

AT A GLANCE

WHO: Fetzer Architectural Woodwork

WHAT: Provider of architecture-specific woodwork as well as custom-made store fixtures/implements for retail industry throughout U.S., and in both China and New Zealand

WHERE: West Valley City, Utah

WEBSITE: www.FetzerWood.com