A Morton Frame of Reference

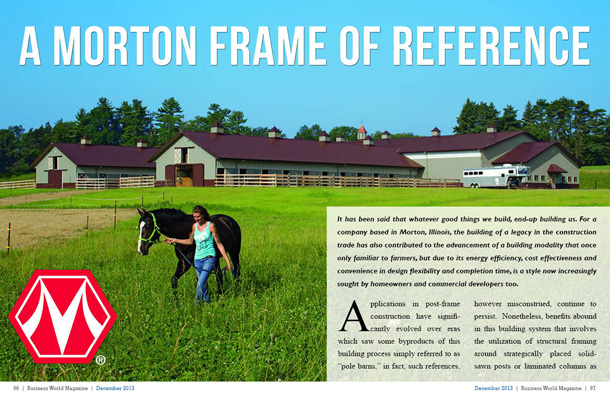

It has been said that whatever good things we build, end-up building us. For a company based in Morton, Illinois, the building of a legacy in the construction trade has also contributed to the advancement of a building modality that once only familiar to farmers, but due to its energy efficiency, cost effectiveness and convenience in design flexibility and completion time, is a style now increasingly sought by homeowners and commercial developers too.

Applications in post-frame construction have significantly evolved over eras which saw some byproducts of this building process simply referred to as “pole barns,†in fact, such references, however misconstrued, continue to persist. Nonetheless, benefits abound in this building system that involves the utilization of structural framing around strategically placed solid-sawn posts or laminated columns as opposed to conventional applications involving studs. After implanted in the ground or surface-mounted to a foundation, columns support additions in trusses and framing components that include wall girts, roof purlins and more. As an engineered building system, this modality has proven to provide greater savings in costs, greater energy efficiency and greater convenience than traditional building methods, but without forcing compromises in terms of quality or aesthetic allure. This is has been demonstrated time and time again through the building of churches, high-end homes, centers of commerce and a range of municipal infrastructure, in examples so seemingly singular in structural and architectural design that one would never venture to guess such examples are a reflection of the building practices behind a pole barn. “I think we’re one of the best kept secrets in construction,†says Dan Nyberg of Morton Building Company in Morton, Illinois, a more than century-old, family-owned company whose expertise and operational exceptionality has certainly contributed to this building model’s transition from agricultural or farm-based applications to that of more residential and urban settings. Yet, as Nyberg explains, “There’s a certain stigma some niches have when people think about building … when we’re talking to a church group, doctor or lawyer looking to build a new office, it’s not uncommon for them to have a misheld perception … they all want something that looks classy, and they’ll say, ‘We can’t use a pole barn.’ But some do their homework, and we’ve seen a growing percentage of customers coming, not simply drawn by perception of lower costs, but actually understanding the complete package of advantages.

Beyond the speed in delivery and the affordability, the advantages of this building system include performance values, such as greater energy efficiency. As Nyberg explains, “You don’t have cold spots as compared with stud wall construction … where for every sixteen or twenty-four inches you have a stud that’s basically going to result in a cold spot in the wall.†In post frame construction, due to the manner in which columns are spaced out and the framing goes together, full blankets of insulations can be applied column to column, creating a more effective barrier which ultimately reduces cold spots. Likewise, in standard stick-built or stud wall methodology, unless trusses are done in a special manner, there’s a significant reduction in ceiling insulation as one moves toward sidewalls, a problem mitigated in post frame construction.

Flexibility in interior spaces as well as exterior features further add to the benefits, from brick, stone and other exterior finishes and options in doors and windows to the variety of shingled roofing systems to accommodate all manner of roof pitch, post frame building still allows for the range of applications that enable any structure to stand-out as architecturally unique. “You can make the building look however you want it to look and function however you want it to, too,†says Nyberg. And, as if the advantages in affordability, flexibility and energy efficiency were not sufficient in themselves, Morton Building has added a few other benefits of its own – including a fifty-year, unconditional snow-load warranty and five-year, unconditional wind warranty.

Evolving Expertise

Morton Building has remained a family-run business after more than a century of operating which all harks back to a 1903 enterprise known as the Interlocking Fence Company. Established by the Getz Family, among the earliest of settlers in Morton, Illinois, the Interlocking Fence Company emerged as a major supplier to farmers, specializing in woven and barbed wire, posts, braces and gates which it sold through a mail order basis. Over time, the company expanded into the supply of roofing materials as well as other home goods, such as washing machines. Perhaps, not quite the Sears Catalog in total inventory, but for farmers in the Midwest, the company’s catalog was an anticipated compendium of readily accessible, and necessary, goods. Morton Building still operates from the very same building featured on the cover of the Interlocking Fence Company Catalog from back in the 1920s. Nyberg credits the advancement of post frame construction to resource realities prompted by World War II. To spare impact on resources such as limber and other goods, the government imposed dollar limits on how much farmers could spend on construction. To save resources, he says someone likely got the idea that poles could be used to hold up trusses and framing could be put around it. The farmer could get the building he needed and control costs too. In that era, Henry Getz resolved to expand company operations in the building niche. From a start in corn cribs, Interlocking Fence expanded into the “pole barn†as a major aspect of the operations. Over a number of years that followed, customers would contract to have a Morton-style building from Interlocking Fence Company. Operations ultimately transitioned to focus on construction, thus leading to recognition of the company simply as Morton Building. Nyberg says Henry Getz, now 93 years in age, continues to visit the office almost every afternoon.

Though the family-friendly focus and values of customer-service-commitment have not changed with the changing of years, the company’s market reach has remarkably grown beyond the early farm infrastructure for which this company became famous. Nyberg has a theory as to how that may have been accomplished. “I think a farmer may have gone to church gathering on a Sunday and heard someone talk about how the church needed a new building, but wasn’t sure how to go about building it or getting the money to build it. He might have considered his own machine shed and said, ‘I could fit three hundred people in my shed if we need to,’ and one thing led to the next.†Morton Building has, in fact, constructed numerous churches; no two look the same, and some have even won national awards for building design.

In addition to its legacy in the industry, Morton Building is comprised by an equally experienced composite of professional builders, with some who have continued working here for more than 45 years. Having worked at Morton for a little more than 24 years, Nyberg still refers to himself as a “middler,†but ultimately says having such an experienced team of builders has enable the company’s ability to impart greater efficiency and quality to their customers –a number that today exceeds more than 500,000 as served by the Morton Building construction centers which have been established among 36 states.

Elevating Experience

Nyberg affirms that Morton’s success has, however, stemmed from the company’s ability to offer something which represents what customers want even more than the highest caliber of experienced builders or ability to source the highest quality of engineered materials with which the company works – as he says, “That isn’t enough.â€

Whether dealing with commercial developers or residential property developers, Nyberg says customers today yearn to have “a greater experience when going through the building process.†To accomplish this, Morton embraces a design/build approach, engaging a team of dedicated architects, builders and subcontractors who collaborate from start to finish effectively ensuring that budgets are maintained and deadlines met, with neither surprises nor excuses to be made along the way. It is a process that calls for collaboration and consistent communication with customers to assure that all demands of design and building performance needs are not only understood, but accurately fulfilled.

As Nyberg says, “It is much different today. The focus in the past was more on a product. You  would purchase a building and if it met your expectations, you were happy…. today, people not only want a quality building, but they also want to be able to enjoy the experience of purchasing the building and watching that building go up. There’s a broader expectation of the market. There is a concern, ‘How quick can you get back to me? How fast can you design and configure the building? When is it going to happen and how it is going to happen? What is the crew like?’ People still want a quality building, but they also want an enjoyable experience in buying and watching that construction take place – that’s what we provide.â€

As for the future, Nyberg says Morton is encouraged to see some pick-up in the commercial and residential sectors of its business, areas that were impacted at the height of the economic debacle national recession. While the company weathered the storm by focusing on services to the ag sector which didn’t feel the degree of impact, Nyberg says it is only in the last year that the company has seen increasing demand in home and office construction, as well as “toy-box†projects. “When men have toys, they want toy-boxes,†says Nyberg, meaning structures for the storing of boats, four-wheelers, or even airplanes – Morton has built a variety of toy-boxes too. “We can be positioned the best in company health, when we have a broad range of niches we’re active in …  ag sector has been good and office or warehouse development never totally disappeared, but was running at low level. We’ve seen pick-up in that as well as residential projects, and are much more confident in terms of forward growth than we were a few years ago,†says Nyberg.

Ironically, when the housing market suffered, Nyberg says it was interesting to note how many builders suddenly took interest in post frame construction process. “The number of players in our niche really expanded… suddenly, builders were at the table wanting a piece of the business which never existed before,†says Nyberg. While the post frame construction may appear to be a very simple and easily learned trade, many of these new entries into our market miss some of the details which truly set post frame apart. If history repeats itself, once the housing market picks up these buildings will return to their roots. As Nyberg says, “People are coming and going all the time, not knowing whether or not they’ll be around isn’t healthy attitude verification on the customer side of things.â€

As for Morton Building, it has been mastering the craft for more than 100 years and, as Nyberg will attest, is positioned to further build upon its legacy in the building industry.

For more information, please visit their website at: Â Â Morton Building Company

Preferred Vendors of Choice: