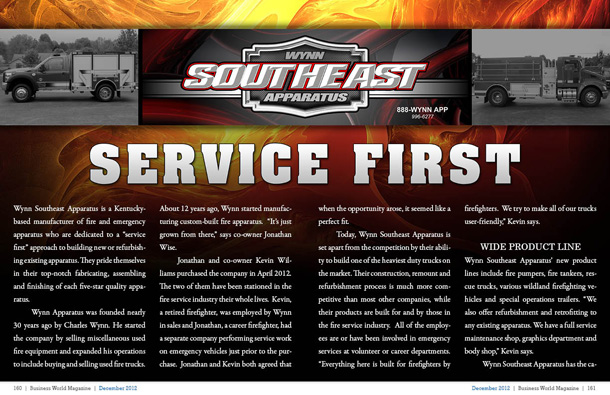

Wynn Southeast Apparatus is a Kentucky-based manufacturer of fire and emergency apparatus who are dedicated to a “service first†approach to building new or refurbishing existing apparatus. They pride themselves in their top-notch fabricating, assembling and finishing of each five-star quality apparatus.

Wynn Apparatus was founded nearly 30 years ago by Charles Wynn. He started the company by selling miscellaneous used fire equipment and expanded his operations to include buying and selling used fire trucks. About 12 years ago, Wynn started manufacturing custom-built fire apparatus. “It’s just grown from there,†says co-owner Jonathan Wise.

Jonathan and co-owner Kevin Williams purchased the company in April 2012. The two of them have been stationed in the fire service industry their whole lives. Kevin, a retired firefighter, was employed by Wynn in sales and Jonathan, a career firefighter, had a separate company performing service work on emergency vehicles just prior to the purchase. Jonathan and Kevin both agreed that when the opportunity arose, it seemed like a perfect fit.

Today, Wynn Southeast Apparatus is set apart from the competition by their ability to build one of the heaviest duty trucks on the market. Their construction, remount and refurbishment process is much more competitive than most other companies, while their products are built for and by those in the fire service industry.  All of the employees are or have been involved in emergency services at volunteer or career departments. “Everything here is built for firefighters by firefighters. We try to make all of our trucks user-friendly,†Kevin says.

Wide product line

Wynn Southeast Apparatus’ new product lines include fire pumpers, fire tankers, rescue trucks, various wildland firefighting vehicles and special operations trailers. “We also offer refurbishment and retrofitting to any existing apparatus. We have a full service maintenance shop, graphics department and body shop,†Kevin says.

Wynn Southeast Apparatus has the capability to offer any apparatus they manufacture on a commercial chassis, which includes International, Kenworth, Peterbilt, Ford, Chevrolet and Freightliner, or on a custom fire truck chassis, which includes Spartan or HME. “All of the bodies we’re building have been in production for at least 10 years. We’ve never had a warranty claim related to a defect in our body fabrication,†Jonathan says. “Our quality control is working pretty well.â€

The newest service they offer is refurbishment and remounting of ambulances. Each vehicle they receive is handled and inspected on an individual basis, which allows for more personal service and customization to meet their customers’ needs. After the inspection, they will disassemble the unit and move it to their body shop for body work and painting. After the unit is painted, it is moved to their fabrication shop to be remounted onto a new chassis and then reassembled with new interior and electronics.  Upon completion of reassembly, the custom graphics package that has been chosen by the customer will be applied to the unit.  The final production step includes a test drive, cleaning, detailing and a final inspection prior to pick-up or delivery.

For Wynn Southeast Apparatus, the key to maintaining their five-star products is staying on the cutting edge of ever-changing technology. They stay up-to-date through constant research, sharing information at trade shows, and from Jonathan and Kevin’s personal background and experience in the fire service industry. “As far as the chassis, everything is top of the line with up-to-date technology that comes right from the vendor we’re using for the particular chassis,†Jonathan says.

“As far as the electronics – warning lights, sirens and other safety features – we stay up to date and receive all the information and technology as soon as it becomes available.  As soon as there’s something new and available, we add it to our vehicles.â€

After delivering a quality product, Wynn Southeast Apparatus makes it a priority to follow up with excellent customer service. “At least 50 percent of what we do is customer service, along with a good quality piece of equipment,†Jonathan says.

Warranty packages are provided for each remount, refurbishment or new apparatus to guarantee the lifespan of the product. If a truck breaks down or has any problems, they have a 24-hour response time to fix any issue a customer may have. “You call and we respond,†says Kevin.

The company employs a staff of 24, all of whom make up a “very good team,†Kevin says. Every employee knows each other on a first-name basis, which helps to foster a positive and open work environment. “We listen to their ideas and we all work together on problem solving and coming up with new ideas. Everybody plays a role in our team,†Kevin says.

“We’re all just one big family here,†Jonathan adds.

Five-star product

While the global financial crisis posed a major challenge for most industries, Wynn Southeast Apparatus managed to avoid most of the effects because of their continued focus on delivering five-star quality products and service. “It goes back to the fact that we build a high quality apparatus and people know that,†Jonathan says. “I think that’s what has kept us from falling behind.â€

What has been an obstacle for them, however, is the availability of vehicle chassis’. This is due to plant shutdowns at vendor facilities based on a lack of orders nationwide. “That hurts us from time-to-time,†Jonathan says. “It forces us to keep vehicles in-stock that isn’t necessarily sold. On the flip side, that probably helps us a lot of times since we have a chassis available where other manufacturers do not.â€

The company looks toward the future with a focus on new ideas and modifications to their existing line of apparatus, and are always looking for input from the fire line. One of the new products they’re looking to add to their diverse five-star product line, in the not-too-distant future, is an ambulance body.

Looking ahead long term, Jonathan and Kevin want to grow the business, but not grow it too large – they never want to lose the personal level of service they’ve maintained with their customers. “We can just do about anything,†Jonathan reiterates. “Every truck we build is custom and they’re all built one at a time. Our customers always receive their apparatus exactly the way they want every time.â€