Cast With Confidence

“In the middle of difficulty lies opportunity,†observed Einstein. For two brothers who have continually capitalized on opportunity, earning respect throughout the manufacturing industry in the process, the road to professional success may have begun with a few slips on the ice and trials-by-fire, but such setbacks couldn’t stop them from transforming a Massachusetts-based enterprise into a world-leading provider of aluminum castings which have proven crucial to helping other industries overcome their own engineering difficulties.

For those clinging on the capabilities compelled by advances in the manufacturing of computer chips, or for those whose lives have benefitted by the just-in-time diagnostics deployed by medical imaging devices; for those who draw inspiration from the efficient illumination of an LED lighting system, and yes, even for those that revel in the repast of a good hamburger without suspicion about the sanitary conditions of the mechanism used to process the meat – a word of special thanks should be shared for a Palmer, Massachusetts, company that has played an important role in the fulfilling of all those processes.

Palmer Foundry has taken the trade craft of casting into corridors of industry once imagined as inaccessible to the practitioners in such processes; a methodology that involves molten aluminum and alloys poured into a mold to produce a product that helps impart functionality to some other apparatus. In the case of Palmer Foundry, these are castings of ultra-high quality with capability to perform under the most rigid and demanding of specifications. Palmer Foundry produces the containers in which computer chips are manufactured, the vacuum chambers critical in the manufacturing of highly sophisticated analytical instruments (serving the entirety of the mass spectrometer industry), from the reaction chambers used in the manufacturing of LED lights to that allowing for gas chromatography – the system so many scientists use for analyzing and interpreting the chemical and particle composition of almost anything (high drama on shows like CSI). Palmer Foundry’s castings also are found among the implements used in the processing of foods, robotic medical devices, the motorized-mechanisms that serve the oil & natural gas industry, and a lot more. The diversity of its market penetration has been born from Palmer’s quality standards, pioneering innovations and persistence in advancing industry understanding about the range of applications in which aluminum castings can so effectively serve. Palmer’s casting solutions have successfully spared customers from unnecessary burdens of cost, time and frustration, all thanks to the operational ingenuity of a team led by Dave and Bob Logan.

Transitional Triumph

The Logan Brothers acquired Palmer Foundry a little more than 13 years ago. The enterprise was actually begun in 1951 when Roderick and Evelyn Jensen began operating from a small garage located on Pleasant Street in Palmer. By 1960, business had grown enough to compel the Jensen family to establish a larger facility situated only a few miles away on a site off Mt. Dumplin Road.

In this same era, the Logan Brothers were being raised in Montreal, Canada, and were very engaged in activities succinct to societal rites-of-passage particular to Canada, which is to say, they played a lot of hockey. Dave, who is ten years older than Bob, excelled in the sport and went on to earn athletic acclaim as an indomitable defender in a career that spanned more than 200 games for teams that included Chicago Black Hawks and the Vancouver Canucks. Dave Logan was said to be aggressive, but not reckless, and he went head-to-head, stick-to-stick, against some of the mightiest power forwards ever procured by the league. Dave Logan had many fans, but there may have been none who cheered more enthusiastically than his little brother. As Bob Logan says, “I was 14 years old watching my brother play in the NHL. For me, he was absolutely an inspiration with his sheer will and desire. I watched it all and just marveled.â€

Dave Logan eventually married and after retiring from hockey, successfully ran a business owned by his wife’s parents. As for Bob, he too had certain prowess as a hockey player, but also the opportunity and means to enroll in college – an opportunity that had not been so readily afforded to his older brother who ground out a college degree over 9 years. Big brother Dave not only encouraged, but strongly emphasized the importance of earning a college degree. Bob went on to play college hockey at Yale University while earning a degree in mechanical engineering. Upon graduation, Bob Logan followed his brother’s footsteps into the NHL playing 2 seasons with the Buffalo Sabres and their farm affiliate, one season with the Los Angeles Kings and their farm affiliate, and 2 seasons in Europe.  He then started a new career in product development for a sporting goods firm.

In Massachusetts, Roderick Jensen had passed away, passing the torch of Palmer Foundry leadership to his son, Frank Jensen, who possessed a certain forward-thinking on technology and applications in which aluminum castings could serve. The company still didn’t have a diversification in industry service, but it was making inroads. Meanwhile, after the company Dave Logan served was sold-out to another firm, he began seeking other employment, something which ultimately proved difficult even for a former professional hockey player with business management experience. “It was a very frustrating time for my brother. He looked at a lot of jobs, but no one would hire him,†explains Bob.  Dave Logan switched his focus to go out and purchase his own business. Bob Logan left his job with the sporting goods firm to join his brother in the search for a company. Bob says, “It was a little stressful as my second daughter had just been born and there was no income coming in.â€

Dave identified a private equity group that agreed to back him, and after an exhaustive search for a company which had all the right ingredients for growing success, we purchased Palmer Foundry.   As Bob says, “We saw the foundry and we really liked Frank Jenson. We liked the people that worked there and their work ethic. We also like the technology side of the business and the market it was serving. We felt that it had a lot of potential.â€

As part of their acquisition of the company, the brothers funded an expansion project which would lead to the opening of a new, larger facility on the same ten-acre site. The new facility was about 80 percent complete when tragedy struck. A fire swept through the existing 35,000 square-foot plant destroying most everything in its wake, and though no one was physically injured, the impact to the business was grave.

Fortunately, “We had insurance,†says Logan. It was a year to the date since the brothers assumed ownership of the company and now they had a decision to make: take the insurance reimbursement and get out, or go through the arduous process of operational restoration? Considering the employees they had come to know so well, as well as the clients who were depending on them, the brothers refused to give-in. “In life, people can get knocked down a lot, but they should never stop getting up. That’s our personality, that’s just who we are, and the fire was difficult, but we put one foot in front of the other figuring out how to take care of our customers, get things back to running and we came through it,†says Logan.

Restoration and Innovation

In short time, the new, larger facility was up and running. The Logans resolved to not only come back, but emerged bigger and better than before. They not only invested in new equipment, but thoroughly analyzed every aspect of their operational systems which soon resulted in their achieving greater efficiencies, product quality and capacity to serve. They implemented automation and enhanced technology tools. They also developed a system for recycling sand. As they formerly had at least two truckloads of sand being hauled-in and hauled-out each day, only being used once, the new system allowed for the material to be recycled, in fact, the company still recycles some 16 to 20 million pounds of sand per year. “We felt like we couldn’t stop looking at what’s next,†says Logan. “We kept asking, ‘What can we do better?’ What can we do to make us stronger as a company?’â€

The obvious answer can now be found within the castings produced by Palmer. Over the years, the company has produced components from new alloys that include: HyDuct5™, an alloy that is resistant to corrosion, has excellent anodization properties and is perfect for applications where high ductility is required (compared to 356-T6 and 356-T51 alloys, this has a higher ultimate tensile strength of 35,000 versus 33,000 and 25,000 respectively and an elongation value of 9% versus 3% and 2% respectively); VaPore®, a vacuum-tight aluminum casting produced from a proprietary process used throughout industries with a spotless performance record (no field failures due to casting defects or vacuum leaks); and Stable-Cast® , a proprietary series of heat-treated aluminum casting effective for high precision applications. Stable-Cast® provides dimensional stability without sacrificing machining properties (machining can be high speed and distortion fee without interrupting the machining for intermediate stress relieving).

Critical to Palmer’s success was convincing others in industry of the capability in their castings. Logan says castings are sometimes maligned as being low-tech or unclean, and therefore unable to serve in high tech or clean applications. Of course, as Logan explains, computer chips are manufactured under very demanding standards of cleanliness. If Palmer Foundry’s components can serve that market, it could also serve others. The company has since diversified and continues to serve a range of industries involving all manner of analytical instrumentation as well LED lighting.

Palmer Foundry’s ability to create large and complex components (some up to 1,400 pounds) has eliminated the need for companies to rely on welded fabrications. In one case, Palmer Foundry was able to produce a single casting of a component that formerly relied on more than 85 welded pieces. This capability has been especially successful in food processing or slaughterhouse operations, where the welded seams and grooves in a mechanism would otherwise capture debris and serve as a breeding ground for dirt and bacteria such as E-coli.

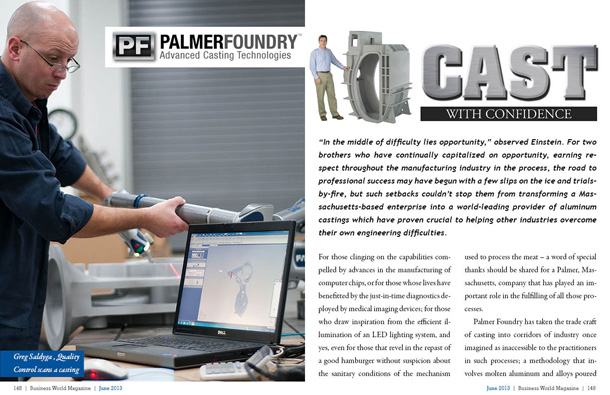

As an ISO 9001:2008-certified organization, Palmer Foundry makes no compromises when it comes to quality, nor does it clients. Palmer Foundry ensures the quality and integrity of the components it produces through a state-of-the-art, laser-based methodology which was totally new to the industry when they adopted it. The technology significantly improves the accuracy and efficiency of quality control inspections, and enables the comparison of both solid model and casting in three dimensions.

Any differences between the solid model and the casting can be immediately identified. The differences are then illustrated in an output that includes 3D imagery, detailed data sets, graphs and narrative. The system also helps identify the origin of problems, making it possible to ascertain whether the issue comes from design specifications, the solid model or the pattern. The technology has empowered Palmer Foundry to provide enhanced design assistance, rapid prototyping and capacity to recreate complicated shapes in a manner that is efficient, fast and accurate.

Logan says the company has essentially deployed technology to allow for monitoring and measuring of company operations. “We know what is happening with our equipment at any time of operation or non-operation. We’re monitoring all processes and parameters and getting feedback of data continuously which helps us better understand exactly how we’re functioning. We’re constantly striving for improvement and that requires measuring. In hockey, you have to know how many shots you made, how many hits, how many blocks. In business, you have to keep up with your stats too,†says Logan.

Of course, in business, you have to keep customers too. Palmer Foundry is shipping components to customers throughout the world today, and Logan says he is confident that the company will continue to grow. In fact, Palmer Foundry secured town permits to add 10,000 square feet of space to their facility this past year. Logan says as more industries come to understand the value, strength and compositional capability of their aluminum castings, there will be new opportunities and new applications in which the company is prepared to perform. As Logan affirms, “One of our goals has been to raise awareness because casting isn’t typically the first thing in an engineer’s toolbox… but this is a technology that can work in high-tech applications … it can be used for a lot more than just making manhole covers.â€

For more information, please visit their website at: Â Palmer Foundry