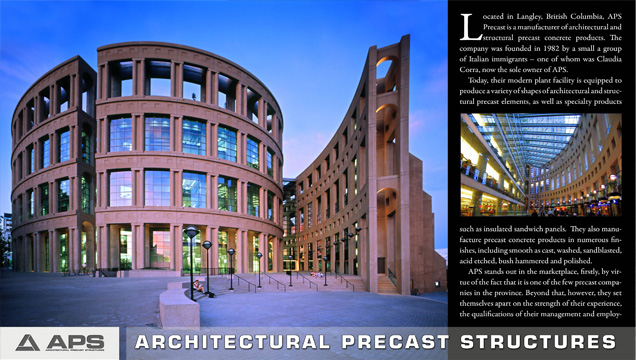

Located in Langley, British Columbia, APS Precast is a manufacturer of architectural and structural precast concrete products. The company was founded in 1982 by a small a group of Italian immigrants – one of whom was Claudia Corra, now the sole owner of APS.

Today, their modern plant facility is equipped to produce a variety of shapes of architectural and structural precast elements, as well as specialty products such as insulated sandwich panels. They also manufacture precast concrete products in numerous finishes, including smooth as cast, washed, sandblasted, acid etched, bush hammered and polished.

APS stands out in the marketplace, firstly, by virtue of the fact that it is one of the few precast companies in the province. Beyond that, however, they set themselves apart on the strength of their experience, the qualifications of their management and employees, their high technology plant, and their superior quality control. Even more, they are highly specialized in architectural precast. They do structural precast work too – and they do it well, says Chief Engineer Merhdad Ahmadi – “but with architectural precast we have the experience, the people, and the capabilities to do it right.â€

“Our establishment is particularly great and advanced at creating architectural forms of complicated shapes and different textures,†he adds. “We can do so many varieties of finishes.â€

Another advantage APS Precast has in sticking out is the second-to-none reputation they have developed over their 30 years of doing business. That reputation attracts clients and partners, and is invaluable in getting APS Precast through a potential client’s door. “They all know us, and so do all the architectural firms,†says Mehrdad.

Once through that door, APS retains its clients and fosters relationships with them by staying in contact. “We keep in touch with them,†Mehrdad says. “We often go to their offices to meet them and discuss future work, and that’s how we market ourselves.†When working with a client, APS will also assist in selecting economical and attractive solutions to their cladding and structural needs, and work closely with the design team to establish a budget that will not be exceeded.

Internally, APS Precast employs approximately 40 people, and the company’s relationship with those people is even stronger than its relationship with customers. “The culture that the owner has created in APS is to dedication – employees are all dedicated to their work,†Mehrdad says.

In his position as Chief Engineer, Mehrdad’s own strategy to foster that dedication has been to get people involved. “I believe if you get people to have a sense of ownership in their job, and their product, they’ll perform to their highest capacity,†he says. “That’s how we implement our culture.â€

As proof of their strong culture, Mehrdad cites the numerous employees that have been with the company for over 30 years – people who have essentially been with APS since its inception. He also cites the fact that a year and a half ago their workers decided to decertify their union, despite being unionized for most of the company’s life. Mehrdad says he is proud of that. “The reason I’m proud of this happening is because I believe the way APS treats its employees was proven to be good enough reason for the employees to trust their employer in a better way.â€

Other points of pride for Mehrdad include the company’s portfolio of work – particularly the jobs they did on the Vancouver Public Library, and the courthouse of Seattle, both of which are landmarks in each of the cities.

Sustainability and technology

When it comes to sustainability, APS Precast is an important company simply as a result of its work with concrete. “Concrete itself is a sustainable material,†Mehrdad says. “It comes from earth, and we simply shape it and form it and put it back together.†Precast concrete is also a durable and long lasting building product, meaning it rarely needs to be replaced or maintained.

Technology-wise, APS is always trying to move forward and improve. Their focus at the moment is mastering polished concrete in a more effective way than they have managed in the past. “One of the jobs we have done polished concrete was Vancouver General Hospital, but we are in the process of procuring a newer polishing technology which is fully automated,†Mehrdad says. He also adds that they are experimenting with creating lighter and thinner concrete utilizing fiber reinforced light weight concrete.

Moving forward, Mehrdad says APS Precast is well positioned to face challenges and to grow. He says the company is looking at a slate of projects that will get the company into the same kind of shape they were in during 2005 and 06, before the global financial crisis hit. “From what I see, we are stepping back up to that level of production we had before.†By five to 10 years in the future, he says their strategy is to grow the business even bigger than what they were in their prime. “The market is promising for the next few years,†he concludes. “I believe that’s possible.â€