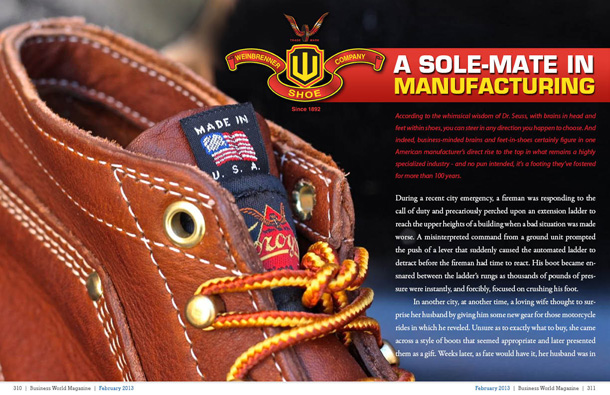

According to the whimsical wisdom of Dr. Seuss, with brains in head and feet within shoes, you can steer in any direction you happen to choose. And indeed, business-minded brains and feet-in-shoes certainly figure in one American manufacturer’s direct rise to the top in what remains a highly specialized industry – and no pun intended, it’s a footing they’ve fostered for more than 100 years.

During a recent city emergency, a fireman was responding to the call of duty and precariously perched upon an extension ladder to reach the upper heights of a building when a bad situation was made worse. A misinterpreted command from a ground unit prompted the push of a lever that suddenly caused the automated ladder to detract before the fireman had time to react. His boot became ensnared between the ladder’s rungs as thousands of pounds of pressure were instantly, and forcibly, focused on crushing his foot.

In another city, at another time, a loving wife thought to surprise her husband by giving him some new gear for those motorcycle rides in which he reveled. Unsure as to exactly what to buy, she came across a style of boots that seemed appropriate and later presented them as a gift. Weeks later, as fate would have it, her husband was in a calamitous accident that caused his feet to get dragged and pinned on the pavement.

These are two isolated examples among a countless number of testimonies that have come from consumers who routinely bestow praise, but more so appreciation, for the wearable work from a very special American company. The consumer accounts detail incidents, so similar to what ultimately happened to the motorcycle rider and that city fireman; cases where one might have easily lost a foot, but were thankfully spared due to the simple fact they were wearing shoes, or boots, manufactured by Weinbrenner Shoe Company.

“Customers send us these kinds of stories almost every day,†says President Patrick Miner. “It helps us stay mindful of how important our work is … how much people depend on our footwear. From its craftsmanship and durability to its quality, it has to perform as needed, when needed, and we take that seriously.†In fact, Miner asserts that his company manufacturers something beyond mere shoes, it is “essential equipment.â€

In the way of branding, say, in that baseball, hot dogs, apple pie and Chevrolet kind-of-way, if the name of Weinbrenner isn’t instantly recognizable, rest assured, the people that depend on their footwear are readily familiar. They include firemen, policemen, construction and chemical industry workers, as well as American military forces that serve our nation here and abroad. These, for whom this nation depends to perform dangerous tasks and safeguard our security, entrust the safeguarding and security of their feet to Weinbrenner Shoe Company. But to be sure, this shouldn’t be considered a new, or even recent, development. Weinbrenner’s distinction as a leading manufacturer and pioneer in footwear dates back more than a century.

Footnotes in History

As President Miner explains, the company all started with a German immigrant named Albert Weinbrenner. His father was a cobbler who toiled in the repair of shoes and boots; working from the confines of a small shop which he established in Milwaukee, Wisconsin. At the age of 13, the father consented to take Albert on as an apprentice. It would take another 14 years, but by age 27 Albert opened his own business by partnering with Joseph Pfeifer, their cobblery became known as Weinbrenner and Pfeifer.

The two spent the next eight years primarily repairing the outsoles of shoes, but in 1900, they purchased the Knoll Shoe Company for all of $1500, a move that once and for all provided means to begin manufacturing their own footwear. The new enterprise was named the Albert H. Weinbrenner Company. In those early years, the company could produce some 60 pairs of boots per day. As their reputation for quality spread, and national distribution resources grew, the company began producing more than 2,000 pairs per day. Weinbrenner then decided to open a larger manufacturing facility. That factory was equipped with its self-sustaining power plant on a bottom floor which not only allowed the operation to save on production costs, but also helped it garner national acclaim in architectural journals of that era. Over the decade that followed, the company branched into dress shoes for women and children, and was so busy that it engaged more leather clippers than any other industry in America.

Weinbrenner’s primary focus was trade-specific functionality, what he called “Job-fitted” design. He saw an opportunity to create shoes customized for the diverse, differentiated needs of tradesmen, from miners and linemen to steelworkers and more. That “job-fitted†aspect would be called to duty with the breakout of World War I. By 1917, the company had become a major contractor to the U.S. Army providing customized boots that served the infantry. By the following year, the company introduced its “Thorogood†line of boots which is still used widely by many trades to this very day.

There is a fashion component beyond the functional elements too. For instance, Miner says the style of shoes initially made for roofers have become popular among general consumer. While the shoe may have been designed to provide special properties of traction and soles that wouldn’t leave scuff marks on tiles, some like to wear the shoes because they make a retro-styled fashion statement.

As far as the company’s most famous footwear, Miner says it would have to be a boot that was unique for its wedge sole and moccasin-style stitching. Originally called the Hike ‘n Camp (The Official Boy Scout Boot), the style was largely adapted by iron workers and other tradesmen to become the company’s best-selling boot style. More than a dozen variations of this style are sold today under the label of Thorogood American Heritage.

Through it all, Weinbrenner has been a leading innovator in footwear manufacturing. It created the first safety-toe work boot in 1938, and went on to secure patents relating the foot-protective nature of their shoe designs as well as other patents involving the production of sole attachment, and much more. Weinbrenner’s fame grew, along with the company which opened new factories in north central Wisconsin and continue to expand upon their lines.

Those innovations kept on marching along, and long after Albert Weinbrenner who passed away in 1949. Employees have since purchased the company, and have continued to expand on their foundation of quality. New lines were established (such as the Wood n Stream Brand) along with new design technology, and more recently, the company developed the “HellFire†line which has been remarkably customized to serve the needs of firemen.

For all their longevity and service to industry, it is easy to understand Miner’s reference to a company slogan, “Working over time.â€

Keeping Up With Demand

Headquartered in Merrill, Wisconsin, since 1969, demand for Weinbrenner’s expertise has exponentially risen in the modern era. That has posed challenges, which in Miner’s perspective, comes not only from the lack of requisite machinery, but lack of skilled workers. Many aspects of production, to this day, are fulfilled by-hand operations, such as stitching. Miner says this is a skill rarely taught by schools today. To compensate, the company has not only had to connect with many cultures, mostly Asian and Hispanic, who over time have mastered this art of craftsmanship. At the same, the company has offered specialized training programs and remains ever agreeable to secure workers that wish to learn.

On the mechanical side, the company is still making use of mechanisms invented long ago, but no longer. Miner says his employees have also become equally proficient in machine repair. Yet, these are new times which afford implementation of new technologies, and again, Miner asserts that Weinbrenner will be at the forefront of its industry in adapting such innovations for their manufacturing purposes. The company is investing in new automated systems as well as new equipment to better their efficiencies. Miner says such enhancements will aid in production without compromising the quality for which Weinbrenner is so respected. The company has also currently partnered with the German engineering giant of Desma, who is producing specialized machinery solely customized for the needs of Weinbrenner. The company will have the most modern robotic sole injection operation in America, and to have such a device will further its distinction from other manufactures.

Yet, for its heritage, for all its innovations, Miner reminds that company functions basically come down to people serving people. And in this case, he says the workers at Weinbrenner take great pride in their work. As a leading employer in Merrill, Wisconsin, Weinbrenner employees have been unionized since the 1940s, organized today as #688 and #717 of the United Food & Commercial Workers International Union, AFL-CIO, and CLC. On the subject of pride, it seems fitting to note certain terms of Packer-perspective, that Wisconsin is an area where people traditionally don the wearing of cheese-themed regalia as an expression of their pride in football. Such pride is similarly extolled for their footwear. Miner says as an American company, all understand the significance of Buying American, but also embrace the belief that American goods reflect a standard of quality and ingenuity, and this is a tradition they are devoted to follow, and further through the future.

With more than 95 percent of the shoes sold in America being manufactured in other countries, Weinbrenner remains among the last, but most legendary, of shoe manufacturers in America.