impact, so they will continue to work with

us.”

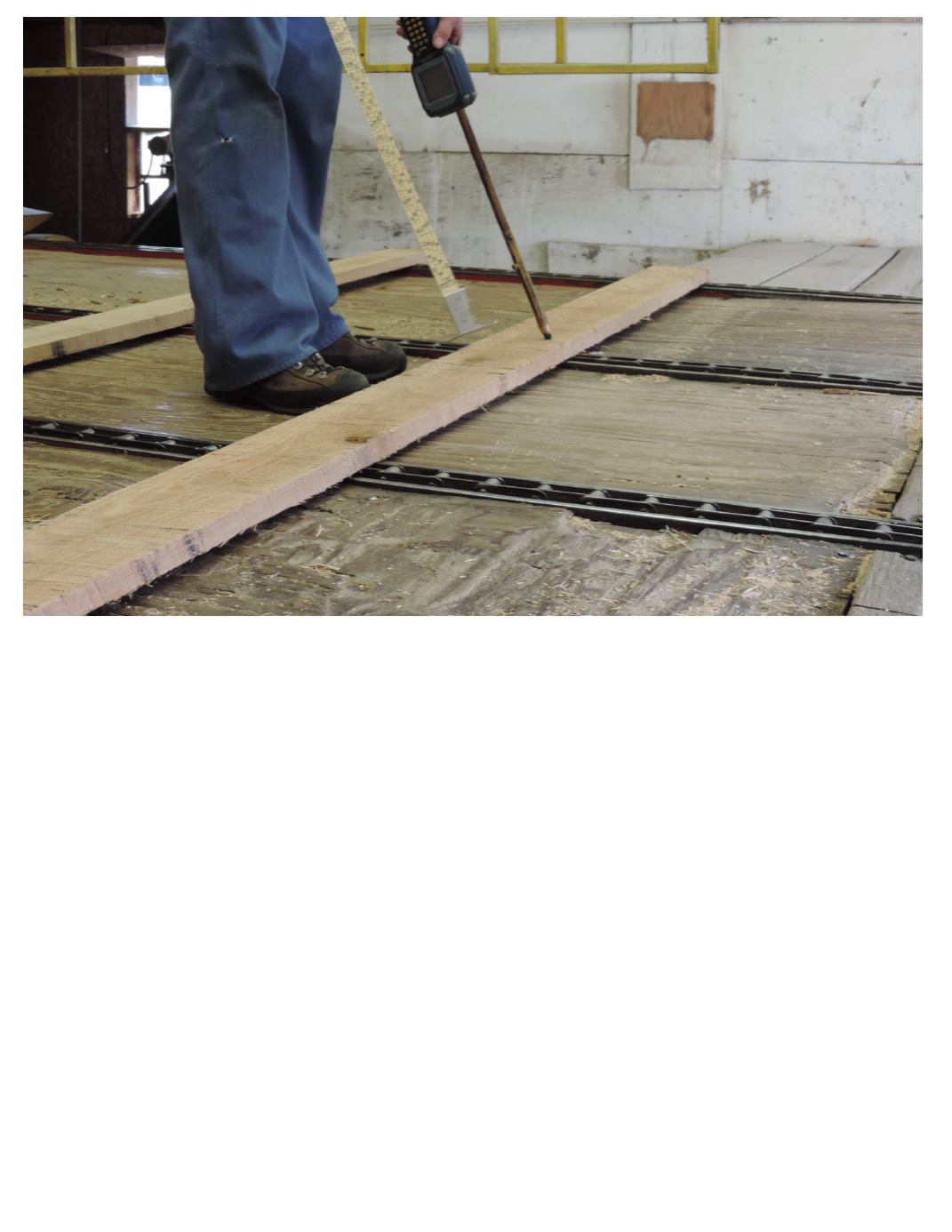

Yoder Lumber works closely with certified

foresters to ensure proper harvesting, and

master loggers use advanced equipment and

techniques to minimize residual damage to

the forest.

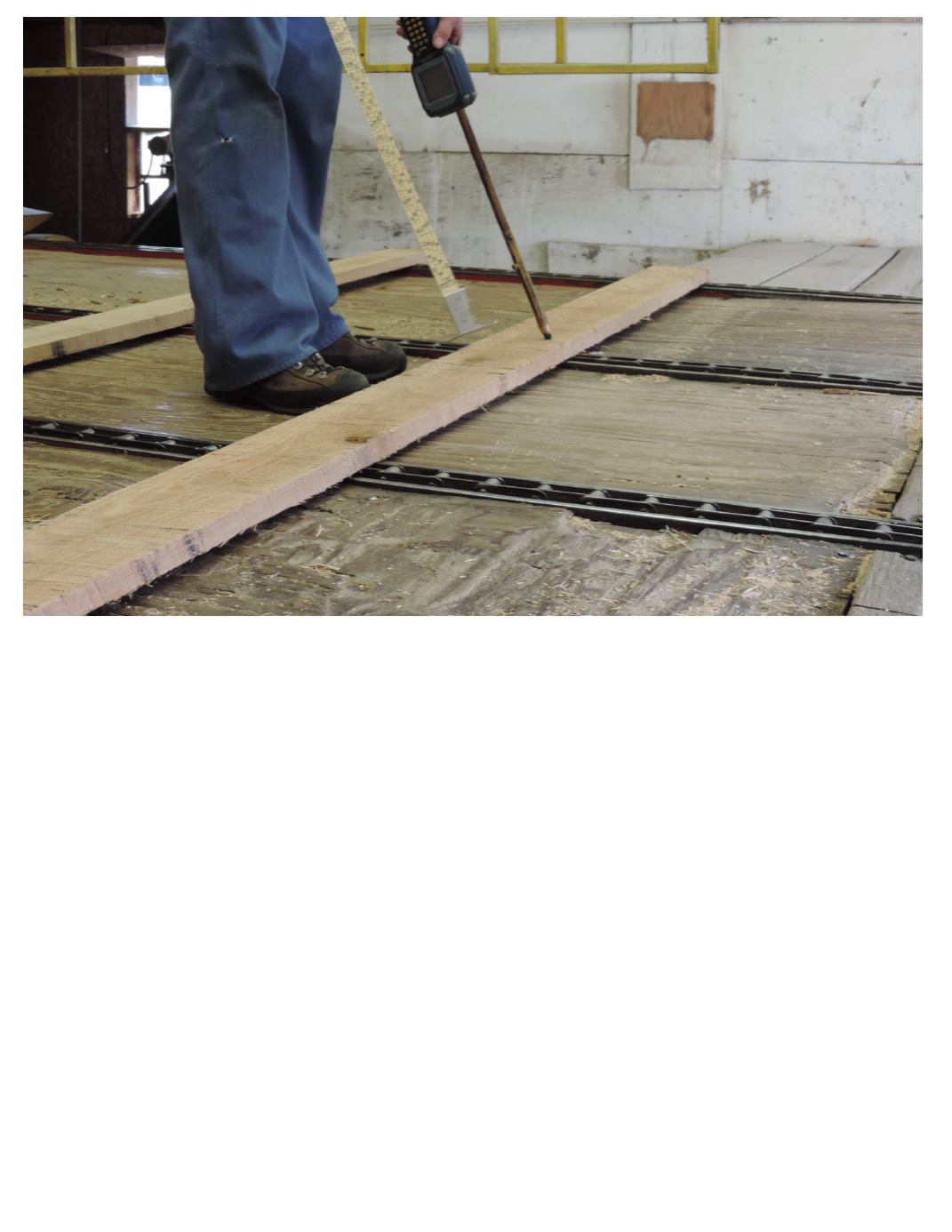

Their facilities are designed to use as much

of every log as possible to reduce waste.

One-hundred percent of the wood-fiber by-

products are used or sold, eliminating the

need to send any by-products to landfills. A

significant portion of thewood by-products

are used to heat 10 kilns, as well as their

offices andmanufacturing facilities.

As much he covets the positive feedback

from the

outside, however, Yoder saidmany

of his best moments on the job have come

because of the internal employee culture

that’s been created over seven decades. And

while the aforementioned dark days a few

years back were undeniably harrowing, it’s

the strength of the company’s core that

reinforced his belief that the dreariness

wouldn’t be permanent.