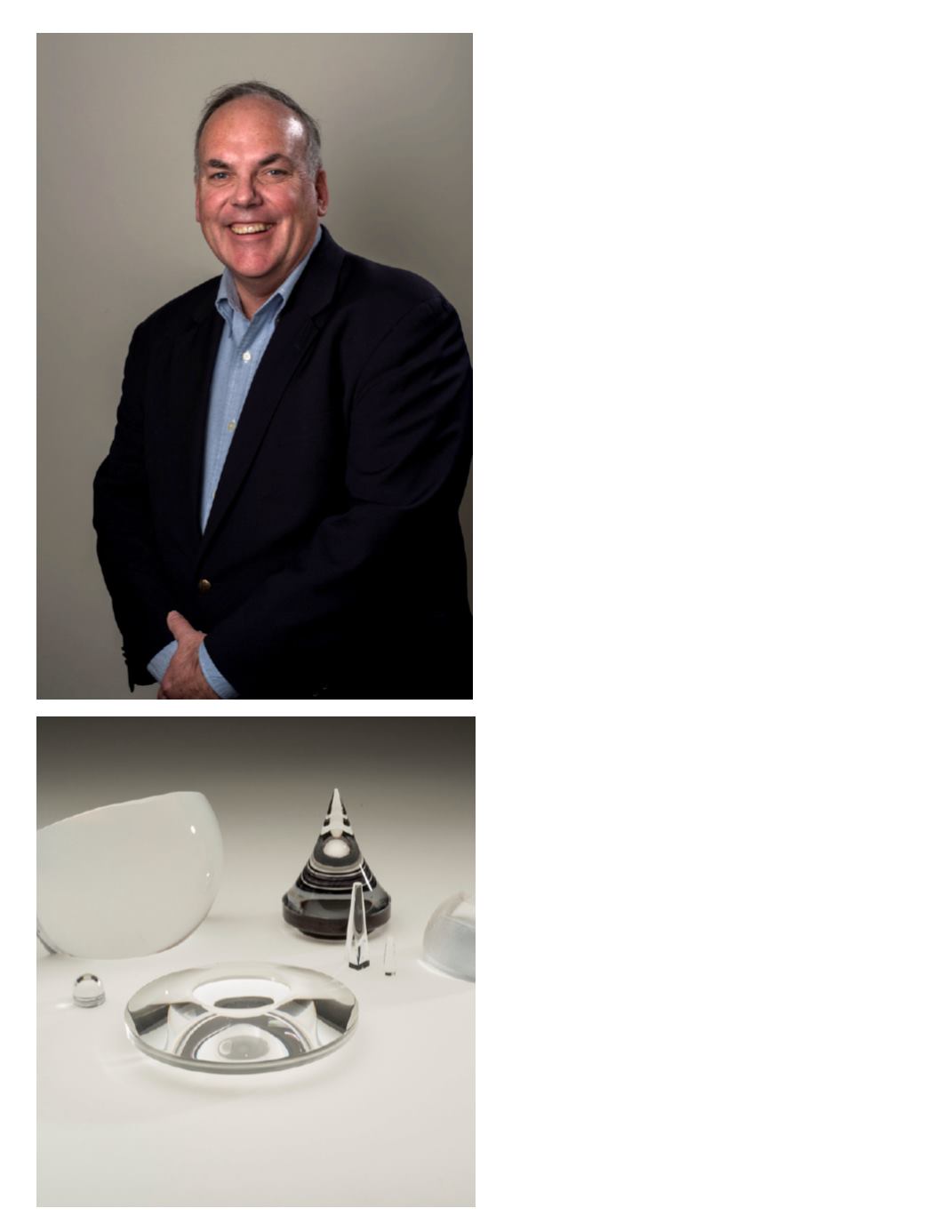

with those technological building blocks

while moonlighting in the basement of a

barn, and, within six years, the company had

accumulated so much know-how in the field

that Kodakmade Optimax its go-to supplier

for those very prototype optics.

By 1996, Optimax was able to use its

computerized machining capabilities to

manufacture prototypes within a week, far

faster than the then-industry standard of 10

weeks. Its Kodak roots were again rewarded

when the film giant committed to funding

75 percent of Optimax training costs as the

company expanded from 20 employees to

more than100.

Kodak, itself, has downsized from a peak of

70,000 employees to less than 5,000, but the

Rochester area has nonetheless evolved into

an innovative hotbed, thanks in part to the

number of companies – including Optimax

– that spun off as the larger entity declined

over twodecades.

“Unemployment is down below 7 percent,”

Plympton said, “because there’s so much

technology that was developed at Bausch &

Lomb (whose local staff plunged from

several thousand to less than 2,000) and

Optimax

| BusinessWorld-

Magazine | 6