Palmer Foundry Palmer | 11

tems which soon resulted in their achieving

greater efficiencies, product quality and ca-

pacity to serve. They implemented automa-

tion and enhanced technology tools. They

also developed a system for recycling sand.

As they formerly had at least two truckloads

of sand being hauled-in and hauled-out each

day, only being used once, the new system al-

lowed for the material to be recycled, in fact,

the company still recycles some 16 to 20 mil-

lion pounds of sand per year. “We felt like

we couldn’t stop looking at what’s next,” says

Logan. “We kept asking, ‘What can we do

better?’ What can we do to make us stronger

as a company?’”

The obvious answer can now be found

within the castings produced by Palmer.

Over the years, the company has produced

components from new alloys that include:

HyDuct5™, an alloy that is resistant to cor-

rosion, has excellent anodization properties

and is perfect for applications where high

ductility is required (compared to 356-T6

and 356-T51 alloys, this has a higher ulti-

mate tensile strength of 35,000 versus 33,000

and 25,000 respectively and an elongation

value of 9% versus 3% and 2% respectively);

VaPore®, a vacuum-tight aluminum casting

produced from a proprietary process used

throughout industries with a spotless perfor-

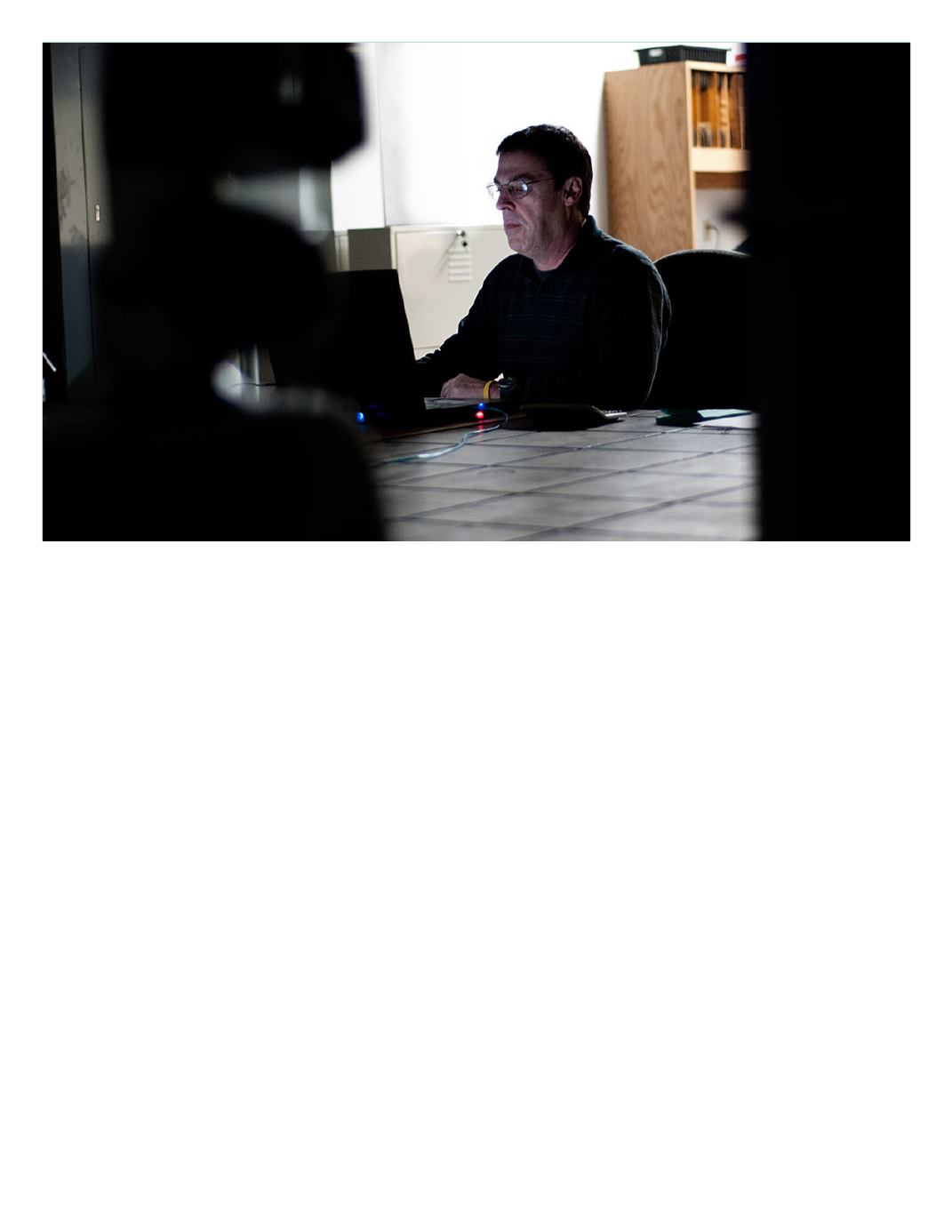

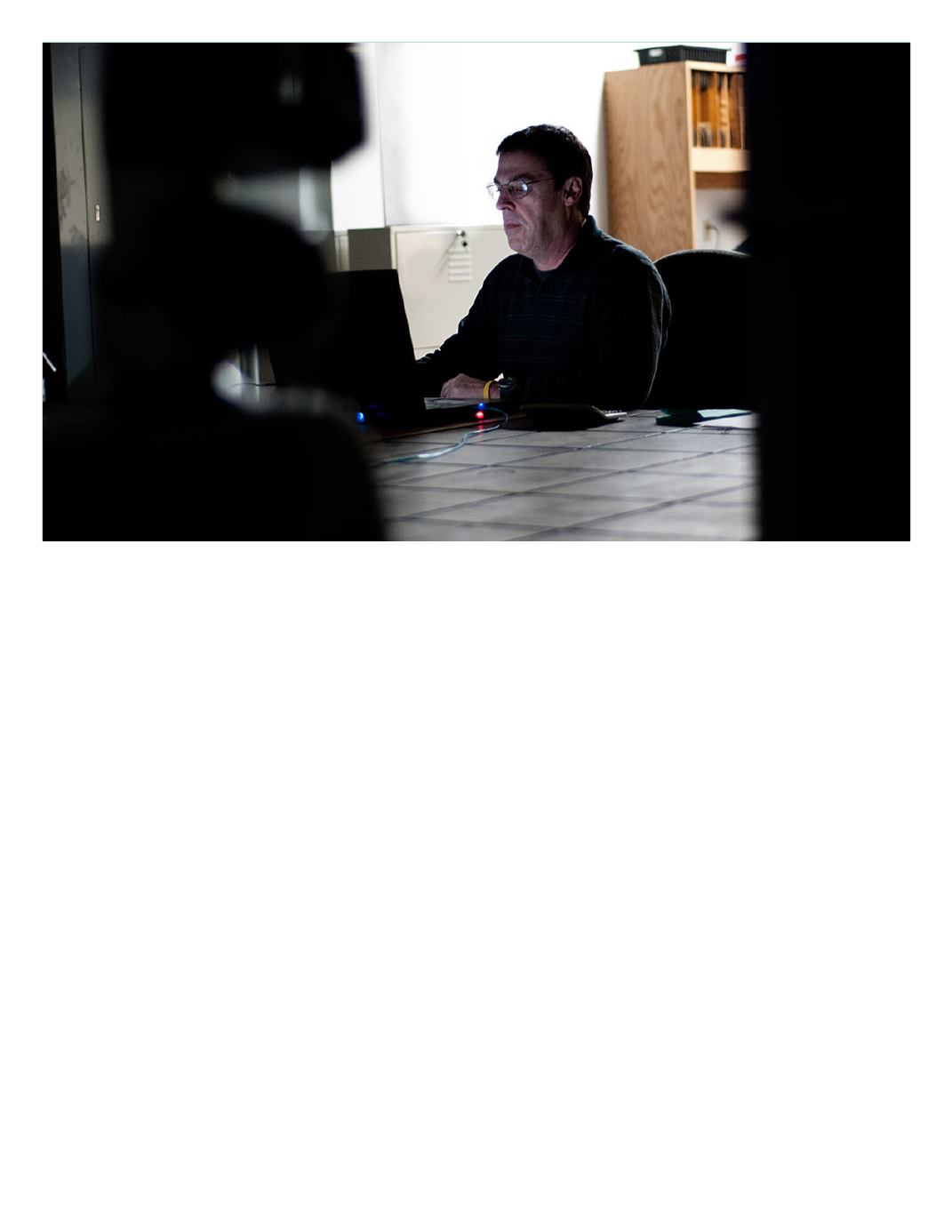

Dennis performs 1st article inspection using laser scan system